Clean Plants, Safe Products: Best Practices for Manufacturing Hygiene in Adelaide

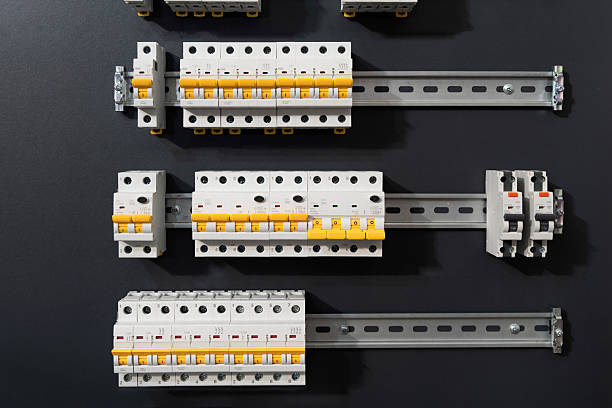

How can manufacturing plants in Adelaide ensure the highest level of cleanliness? Clean plants lead to safer products, and following the best hygiene practices ensures safety and compliance with industry standards. Manufacturing plants, especially in Adelaide, must prioritise cleanliness to prevent contamination and ensure smooth operations. For top-tier hydraulic solutions, explore hydraulic power packs from Hydrastore, known for exceptional quality and functionality. These expertly engineered systems cater to diverse industrial needs, ensuring smooth operation and durability, enhancing efficiency in demanding environments. This article covers some of the best practices for ensuring— a clean manufacturing environment in the city.

Best Practices for Maintaining Industrial Hygiene

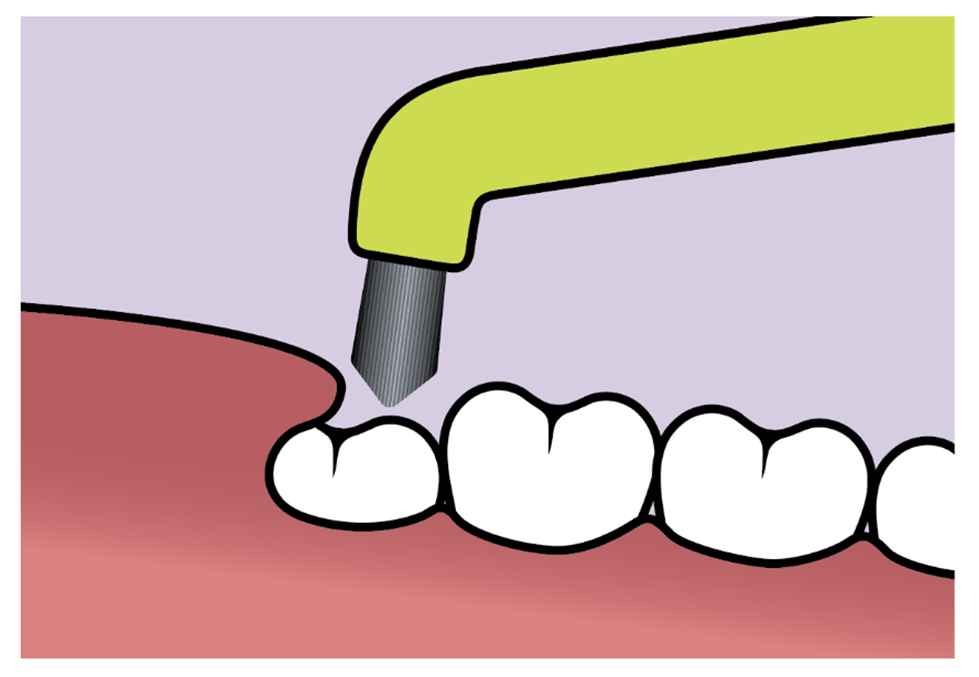

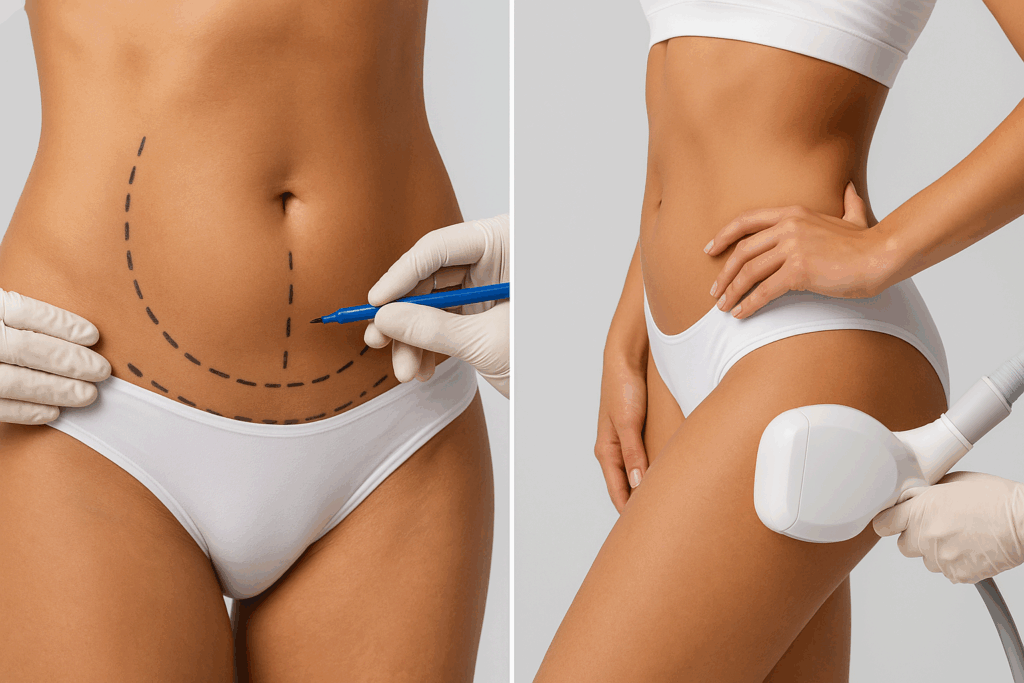

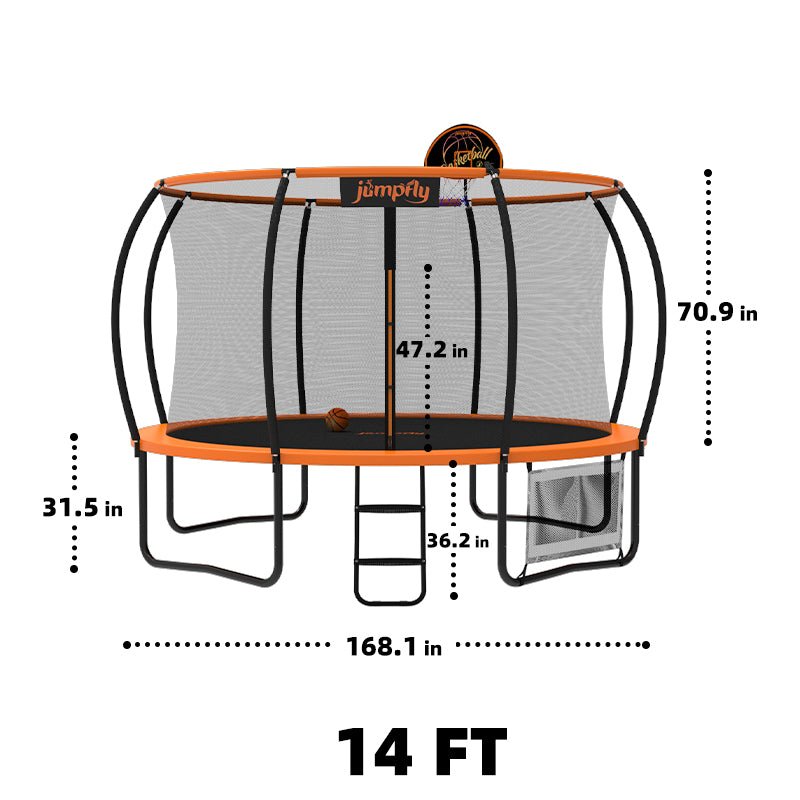

Incorporating an industrial sweeper

Incorporating an industrial sweeper in Adelaide manufacturing plants is a game-changer for maintaining cleanliness and safety. These powerful machines efficiently clean large areas by removing dust, debris, and other contaminants from factory floors. By using an industrial sweeper, companies can reduce the risk of product contamination and create a safer environment for workers.

Prioritise Regular Cleaning

Manufacturing plants should have a strict cleaning schedule. Consistency is key to maintaining a hygienic space. Daily sweeping of floors and regular cleaning of equipment can prevent the build-up of dirt and debris. A well-implemented cleaning routine also ensures that potential contaminants are addressed before they become an issue. Scheduling frequent inspections can help ensure the cleanliness plan is being followed.

Use the Right Cleaning Tools

Not all cleaning tools are created equal. Using the right equipment for specific areas is essential for maintaining cleanliness in a manufacturing facility. An industrial sweeper in Adelaide can make a significant difference for large spaces. These machines are designed to handle heavy-duty cleaning, ensuring floors remain free of dust, debris, and other particles that can harm manufacturing.

Train Employees on Hygiene Standards

Employee training is critical to maintaining a clean manufacturing plant. Workers should be educated on proper hygiene practices and cleaning protocols. When employees understand the importance of cleanliness, they are more likely to follow the guidelines. Training should cover the use of cleaning tools, safety precautions, and personal hygiene standards. Workers must know how to properly clean their workstations, dispose of waste, and store materials safely.

Maintain Air Quality

Air quality is often overlooked when discussing plant hygiene, but it plays a crucial role in maintaining a clean environment. Dust and airborne particles can easily contaminate products, especially in the food and pharmaceutical industries. Regularly changing air filters, using air purifiers, and controlling humidity levels can all improve air quality in the manufacturing facility. An industrial sweeper can also help reduce the amount of dust in the air by efficiently cleaning the floors.

Implement Proper Waste Management

Proper waste disposal is vital in maintaining a clean plant. Trash should be removed regularly, and waste bins should be placed in convenient locations throughout the facility. Ensuring that waste is separated, recycled, and disposed of according to local regulations helps maintain a safe and clean environment. Industrial sweepers can assist in keeping waste under control by quickly collecting debris that accumulates on factory floors.

Regular Inspections and Audits

Regular inspections and audits are essential to ensure the highest hygiene standards are consistently met. These inspections help identify areas that may need additional cleaning or protocol adjustments. External audits can also provide a fresh perspective on improving cleanliness and safety. In Adelaide, manufacturing plants that proactively approach cleanliness through routine inspections can catch potential issues early.

Protect Your Reputation

Maintaining a clean manufacturing facility isn’t just about compliance – it’s also about protecting your company’s reputation. Clients and consumers expect products to be made in safe, clean environments. Poor hygiene can lead to product recalls, legal issues, and a damaged reputation. Utilising tools like industrial sweepers shows a commitment to cleanliness and safety.

Manufacturing hygiene in Adelaide is necessary for regulatory compliance, product quality, and worker safety. Incorporating practices such as regular cleaning, using an industrial sweeper in Adelaide, training employees, and conducting frequent inspections helps maintain a clean and safe facility. By following these best practices, manufacturers can protect their reputation and ensure a successful business.