How to Choose the Right Label Clothing Supplier for Your Brand

What if your brand’s success depends on a single decision you haven’t made yet? Finding the right partner for your clothes is more than just sewing. It’s about trust, meeting deadlines, and keeping your reputation safe. Yet, 67% of new brands face quality or communication problems with their partners.

Your choice of clothing maker affects your profits and customer loyalty. The wrong choice can cause delays, poor materials, or ethical issues. The right partner is like an extra team member, offering precision, openness, and growth.

At MFG Merch, they’ve seen brands improve when they focus on three key things: matching production with goals, ethical standards, and design freedom. Whether you’re starting small or growing big, your supplier must grow with you. Let’s look at how to spot problems early and find partners that help you grow.

Key Takeaways

- Choosing the right supplier affects your product quality, delivery times, and reputation.

- Matching production with your goals prevents costly mistakes.

- Ethical and sustainable standards are now expected in the market.

- Clear communication can cut down errors by up to 40% in making clothes.

- Being able to grow with your business is what sets good partners apart.

Understanding Your Brand Needs

Before choosing suppliers, align your production with your brand’s identity. Focus on who you’re dressing, what you’re making, and how much you can invest. Let’s explore these areas strategically.

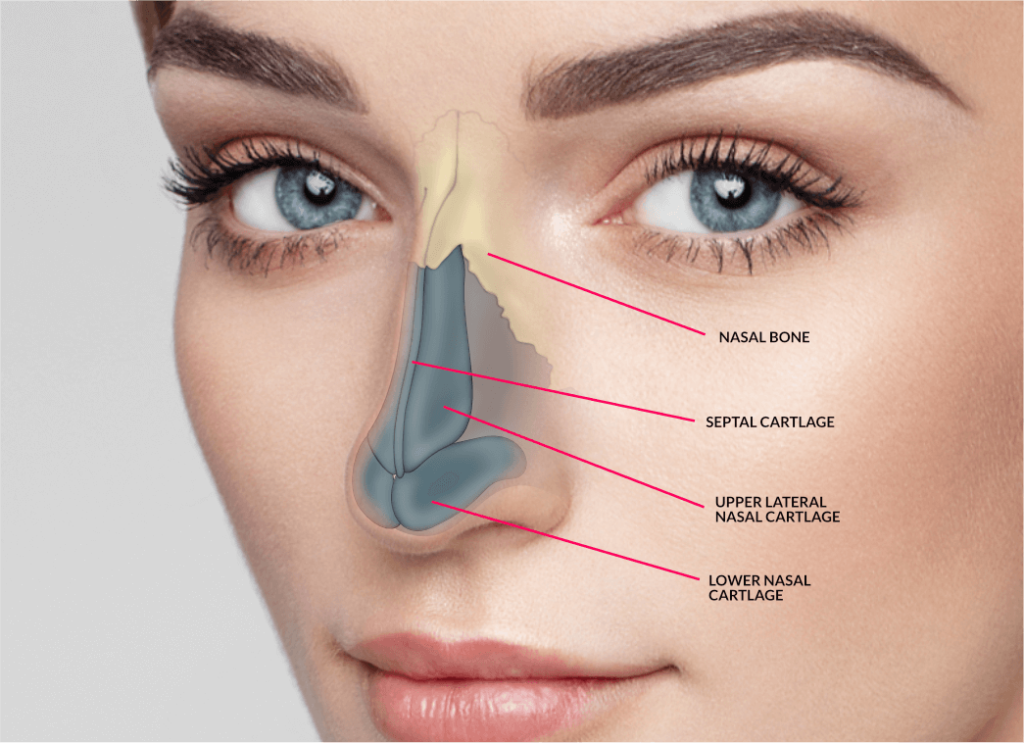

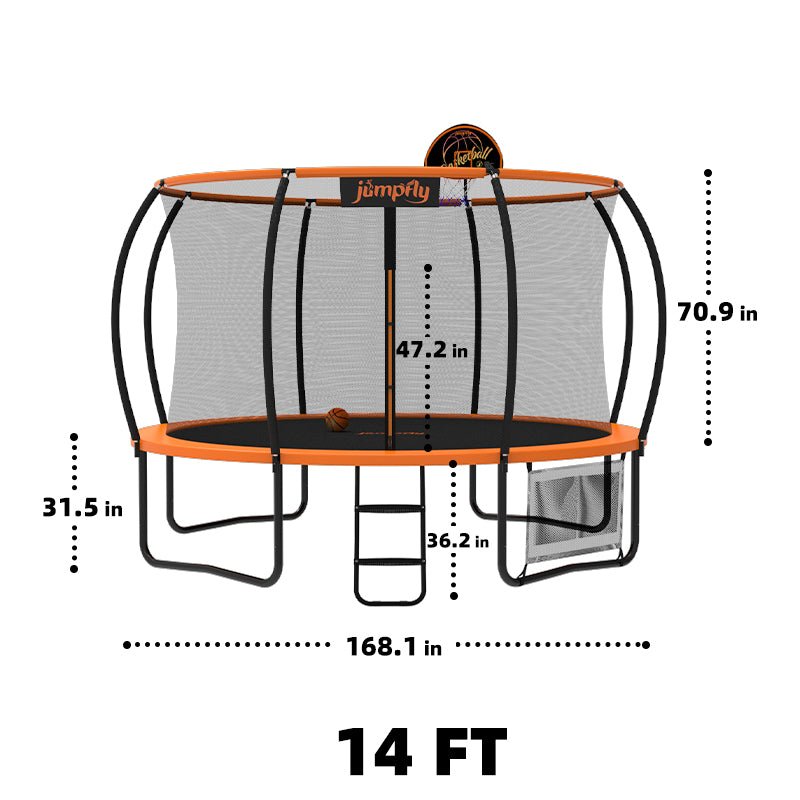

custom clothing labels example

Defining Your Target Market

Your labels and tags are more than just functional. They represent your brand. Think about:

- Is your audience Gen Z shoppers who love bold holographic tags?

- Do luxury buyers prefer simple, gold-threaded woven labels?

- Will eco-conscious customers like recycled paper hang tags?

“Our vegan leather care labels boosted sales by 40% among sustainability-focused millennials.” – Apparel startup founder

Choosing the Right Materials

The type of fabric you choose affects both look and durability. Here’s a comparison:

| Material | Best For | Considerations |

| 95% rayon/5% spandex | Stretchy basics | Soft drape, requires gentle care |

| 100% organic cotton | Eco-friendly lines | Premium pricing, limited color options |

| Poly-cotton blend | Budget-conscious lines | Durable but less breathable |

Pro Tip: Get swatch kits to feel how different clothing brand tags materials work with your fabrics.

Setting a Budget for Production

Find a balance between quality and cost. Here’s how:

- Calculate per-unit label costs × first production run quantity

- Save 15% for unexpected upgrades

- Look for bulk discounts for future orders

Remember, cheap custom clothing labels that fray quickly can harm your brand more than investing in quality.

Types of Label Clothing Suppliers

Choosing the right partner for your clothes is key. It’s about knowing the key differences between supplier types. Your choice affects your profits and how consistent your brand looks.

Manufacturers vs. Wholesalers

Working with an apparel label manufacturer means you get to pick every detail. They start from scratch, perfect for unique sizes, fabrics, or tags. For example, MFG Merch in Jacksonville is great for small batches and quick turnaround.

Wholesalers, on the other hand, have pre-made clothes at a lower cost. They’re good for quick restocks but you can’t customize much. Here’s a quick comparison:

| Factor | Manufacturers | Wholesalers |

| Customization MOQs | Full control 500+ units | Limited options 50+ units |

| Lead Time | 6-8 weeks | 1-2 weeks |

| Cost Efficiency | Higher upfront | Lower per-unit |

Local vs. International Suppliers

Local partners like MFG Merch offer three big benefits:

- Fast shipping (2-5 days vs. 4+ weeks)

- Easy quality checks

- No import taxes

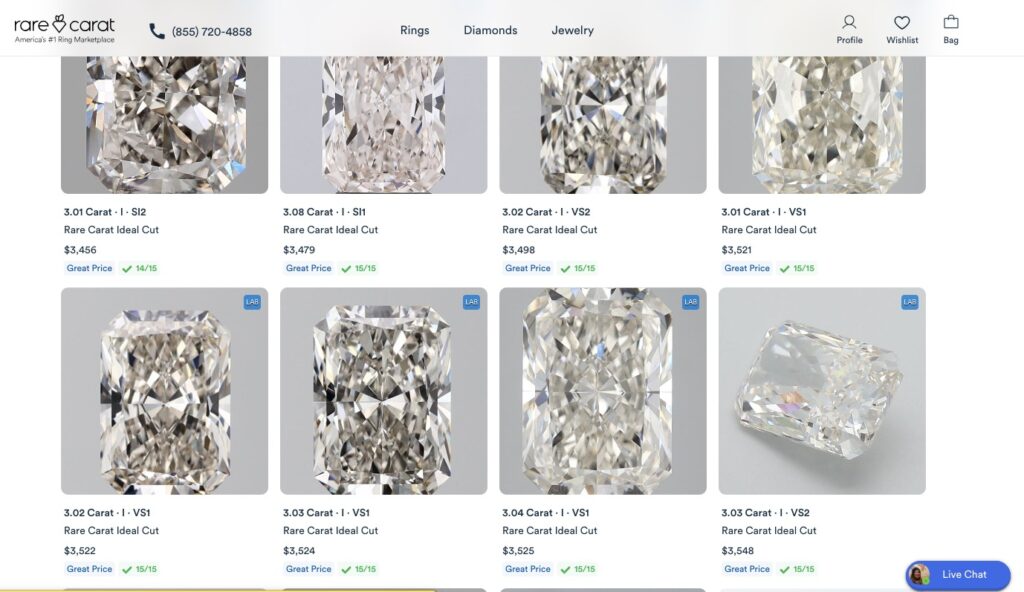

apparel label manufacturer comparison

But overseas suppliers might seem cheaper because of lower labor costs. Yet, there are big challenges:

- Language barriers can cause misunderstandings

- Shipping can be unpredictable

- Minimum orders are often over 1,000 units

“Local manufacturing partnerships reduce risk for new brands – you pay for agility, not just products.”

For white label clothing supplier, think about where you are in your growth. Startups do well with local partners for flexible terms. But bigger brands might mix local and overseas production.

Evaluating Supplier Experience

Choosing a partner for your clothing labels is more than just looking at prices or catalogs. It’s about trusting them with your brand’s reputation. A supplier’s experience can make a big difference. It affects whether your orders are on time, meet quality standards, or handle unexpected challenges well. Let’s explore how to check their reliability.

Importance of a Proven Track Record

Suppliers with years of experience are less likely to surprise you. Look for:

- Production history: How long have they made custom shirt tags or garment labels?

- Client retention: Do big brands keep coming back to them?

- Certifications: ISO or other industry-specific certifications show they follow standards.

For instance, suppliers who’ve handled sudden demand spikes or material shortages show they can handle crises. Always ask for case studies. Real-world examples tell you more than marketing claims.

garment tag supplier evaluation

Checking Client Testimonials

Reviews give you honest views of a garment tag supplier’s work. Here’s how to do it:

- Check testimonials on their website and verify them on sites like Trustpilot.

- Ask for 2–3 references from businesses like yours in size or niche.

- Look for patterns—repeated complaints about late shipments or poor communication are warning signs.

One apparel startup found their custom shirt tags partner had a 40% defect rate by checking LinkedIn endorsements against Google reviews. Don’t overlook this step—your brand’s image depends on it.

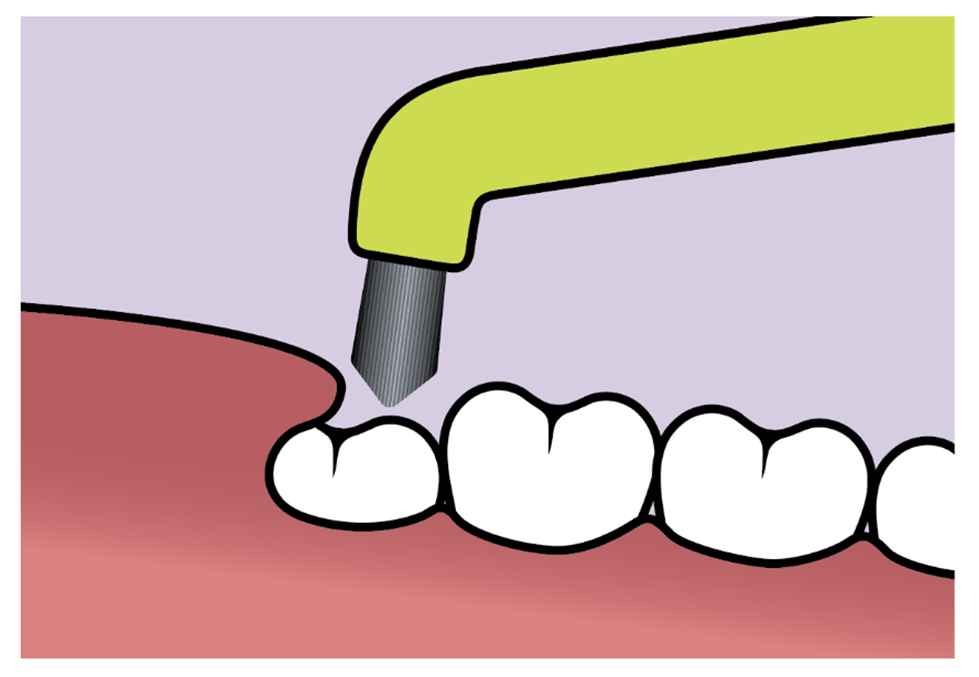

Quality Assurance Practices

Your brand’s reputation depends on the quality of your products. This starts with your supplier’s attention to detail. To gain customer trust, you need partners who prioritize quality control. Let’s explore two key areas where thorough checks are crucial.

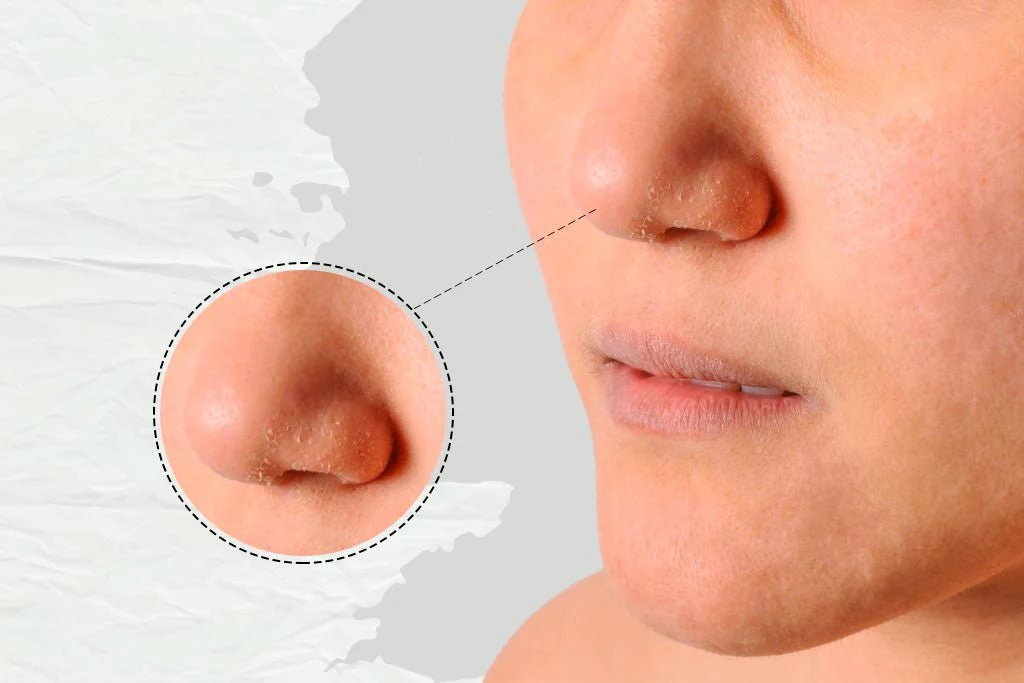

fabric quality assessment woven label manufacturer

How to Assess Fabric Quality

When choosing a woven label manufacturer, always ask for physical samples. Hold the material up to light. Good fabrics should not fray and keep their shape after tests. Here’s what to look for:

- Stitch density: 12-15 stitches per inch means it’s durable

- Colorfastness: Rub samples with a white cloth after soaking in water

- Edge finishing: Laser-cut edges are better than heat-sealed ones

Top fabric label makers like MFG Merch give care instructions early. If tags say “machine washable,” test this by washing samples three times. Any fading or shrinkage could lead to expensive returns.

Understanding Production Standards

Good suppliers follow strict standards like CPSIA compliance. This rule checks for lead content and flammability in textiles. Ask potential partners:

“Can you share third-party test reports from the past six months?”

This helps you find true professionals from cheap ones. MFG Merch’s quality team, for example, does four-stage inspections:

- Raw material verification

- In-process alignment checks

- Pre-shipment functionality tests

- Random batch audits post-delivery

This ensures every label meets your standards. Whether you need eco-friendly hemp tags or glitter-infused polyester designs. Remember, consistent quality today means more customers tomorrow.

Production Capabilities

Your brand’s growth depends on your supplier’s ability to scale with you. It’s not just about making clothes. It’s about building a partnership that grows with your business. Let’s look at two key factors: order flexibility and long-term adaptability.

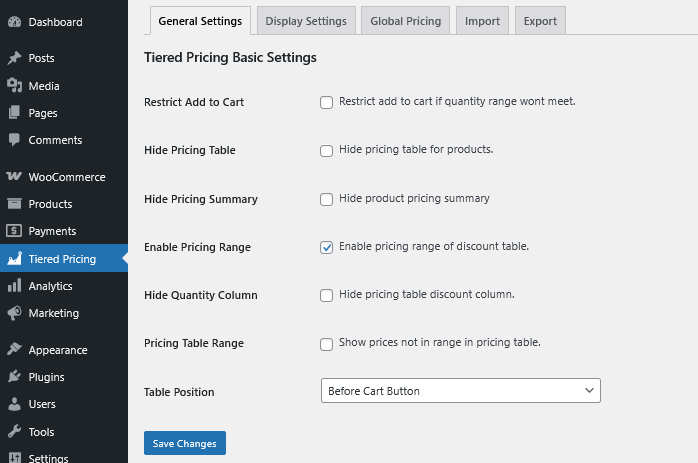

Minimum Order Quantities (MOQs)

MOQs show how many units you need to order to work with a supplier. They vary a lot:

| Supplier Type | Typical MOQ Range | Negotiation Flexibility |

| Large Manufacturers | 500–5,000+ units | Limited |

| Whole sallers | 100–1,000 units | Moderate |

| Local suppliers | 50–500 units | High |

Startups often worry about high MOQs. But, some clothing manufacturers like MFG Merch offer tiered pricing. This lets you start small and grow as demand increases. Always ask about:

- Seasonal discounts for bulk orders

- Payment plans for larger batches

- Custom MOQs for personalized garment labels

Scalability for Future Growth

A supplier that can’t scale with you becomes a bottleneck. MFG Merch is a standout here. Their production lines adjust easily, whether you need 500 or 50,000 units. Scalability is key:

- Rapid turnaround times prevent stockouts during sales spikes

- Multi-factory networks handle sudden order increases

- Tech integrations sync inventory with your sales channels

One brand grew from 200 to 20,000 monthly units with MFG Merch. Their CEO said: “We never lost momentum during growth phases—our production partner kept pace every step.”

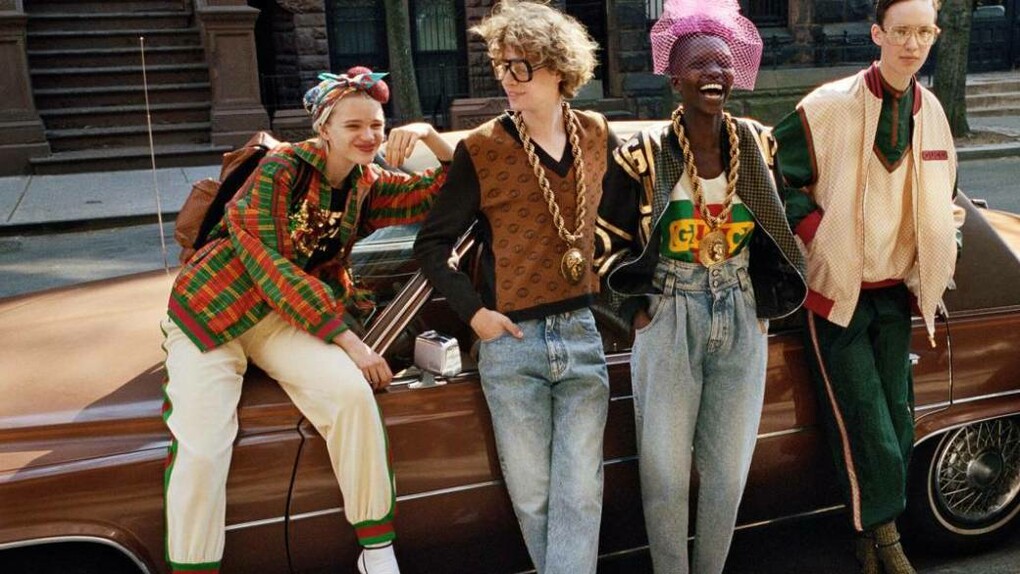

Customization Options

Your brand’s identity is more than just clothes. It’s how you show them off. Custom labels, tags, and packaging make clothes unforgettable. They also tell your brand’s story.

Labels, Tags, and Packaging Choices

Choosing a clothing tag supplier with flexibility is key. You can pick from three branding levels:

- Basic woven labels: Great for new brands, they have your logo and care info

- Printed hangtags: Include QR codes, eco-standards, or your brand’s message

- Full branded packaging: Use tissue paper, stickers, and boxes that match your design

MFG Merch offers a modular system. It lets you start small and grow. One client started with basic labels and now has fancy leather tags. They used the same garment tag supplier for everything.

Private Label vs. Custom Branding

Deciding between pre-made designs or something new? Here’s a comparison:

| Feature | Private label | Custom branding |

| Design control | Choose from templates | Fully original creations |

| Setup cost | $50-$200 | $500 |

| Best for | New brands testing markets | Established companies refining their image |

Many brands start with private labels to quickly enter the market. Then, they switch to custom designs. A MFG Merch partner said: “We started simple, but after 10K orders, we went for custom recycled packaging.”

Communication and Support

Creating a strong partnership with your apparel label manufacturer starts with clear talks and help when you need it. Unlike some services that focus more on rules than people, the best partnerships treat your brand like part of their team.

Why Clear Communication Makes or Breaks Orders

Most delays in the garment world come from misunderstandings. Make sure you set up these key steps early on:

- Dedicated project manager for a steady contact

- Weekly updates with photos

- Quick answers to urgent questions

“Our custom shirt tags order needed three changes – MFG Merch’s team was faster than our own design meetings!”

– Taylor R., Emerging Streetwear Brand

Spotting Customer Service Red Flags

Be careful of these signs when looking at suppliers:

| Issues | Risk | MFG merch solution |

| Generic email responses | Slow problem solving | Named account specialists |

| No after hours support | Missed deadlines | 24/7 production portal access |

| Hidden revision fees | Going over budget | Upfront Pricing lock |

While some treat clients like just another number, we focus on real support. Our apparel label manufacturer offers regular strategy talks. This helps brands tweak custom shirt tags designs before making them, saving about $1,200 in sampling costs.

Sampling and Testing Processes

Getting hands-on with prototypes is your secret weapon for perfecting personalized garment labels before full production. This phase lets you catch design flaws, test material durability, and ensure your vision aligns with reality. Let’s break down how to navigate this critical stage.

Requesting Product Samples

Start with these steps to make sampling work for your brand:

- Specify your requirements: Share exact measurements, thread colors, and label attachment methods.

- Ask for multiple iterations: Reputable suppliers like MFG Merch provide 2-3 sample versions to compare.

- Test rigorously: Wash, stretch, and expose labels to heat to mimic real-world use.

Watch out: Suppliers who rush you into bulk orders without prototyping often deliver subpar quality.

Feedback Loop for Quality Improvement

Turn sample reviews into tangible upgrades using this approach:

- Document every detail – from stitching inconsistencies to color mismatches

- Schedule video calls with your woven label manufacturer to discuss changes

- Request revised samples within 7-10 business days

MFG Merch’s clients see 40% fewer defects by using this three-round feedback system. Their team logs every adjustment in a shared dashboard, creating clear accountability.

Why Choose MFG Merch?

Choosing the right label clothing supplier is key to your brand’s image and customer trust. MFG Merch offers U.S.-based manufacturing at their Jacksonville facility. They make every order fresh to your exact specs, avoiding outdated stock or quality issues.

MFG Merch delivers custom clothing labels and apparel in just 30 days. This is much faster than many overseas competitors. They work closely with you to perfect materials, designs, and packaging. They also handle small batches and grow with your business.

Transparency is a hallmark of MFG Merch. You can visit their workshop at 240 Talleyrand Ave, Jacksonville, FL 32202, or call (904) 677-9505 to talk about your project. They focus on new production, avoiding hidden costs from refurbished or bulk items.

MFG Merch prioritizes your vision, whether it’s private label branding or bespoke tags. They ensure you get samples, revisions, and final products without delays. Partner with them to create a clothing line that meets your standards, from start to finish.

FAQ

How do audience demographics influence clothing label decisions?

Your target audience’s age, values, and preferences shape label choices. For example, eco-conscious buyers might demand recycled polyester tags. Luxury shoppers expect embossed leather labels. A Gen Z-focused brand might choose bold woven labels, while minimalist designs appeal to mature audiences.

What should I check when evaluating fabric quality for custom clothing labels?

Always review the supplier’s material specs. Look for details like 100% cotton satin or 65/35 polyester-cotton blends. Reputable apparel label manufacturers like MFG Merch provide CPSIA-compliant swatches and third-party test results. Avoid suppliers who can’t verify fabric origins or safety standards.

How can I balance quality and budget with a clothing tag supplier?

Prioritize non-negotiable features (like RFID-blocking labels for techwear). Compromise on secondary elements. Many brands use woven labels for core products and printed tags for limited editions. Ask suppliers like MFG Merch about bulk discounts or split shipments to manage MOQs.

Why does supplier experience matter for private label clothing production?

Seasoned garment tag suppliers prevent costly errors. Case studies show brands like Marine Layer succeeded by partnering with suppliers who pre-tested label adhesives. Always verify claims through client references or platforms like Alibaba Trade Assurance.

What red flags indicate an unreliable clothing label supplier?

Watch for vague MOQ policies, refusal to share facility audits, or QVC-style “as-is” disclaimers. Reputable custom clothing label suppliers like MFG Merch provide detailed production timelines. Risky partners often dodge questions about turnaround delays or material substitutions.

How do I test physical samples from a woven label manufacturer?

Conduct real-world stress tests – wash samples 10+ times, check stitch density under magnification, and expose tags to UV light. MFG Merch’s clients use industrial rub tests (ASTM D5264) and adhesion checks (ASTM D3359) to ensure labels survive retail environments. Always compare against industry benchmarks like CPSIA compliance.

What communication workflows prevent issues with clothing brand tags?

Demand dedicated account managers – not generic inboxes. MFG Merch assigns design-to-delivery teams who share 3D mockups pre-production, unlike suppliers with QVC-style impersonal portals. Set clear response-time SLAs and escalation paths for label revisions or shipping delays.