Steel Cabinet Specifications and Maintenance Manual In Manila

Including steel cabinet in various applications, from offices to homes, is a reliable and popular choice. The buildings are typically made from sturdy substances and are recognized for their durability as well as their safety capabilities. Additionally, they’re highly smooth to maintain. The instructions provided in this guide provide a comprehensive overview of the components and materials utilized to construct your cabinet, as well as tips and tricks for putting up and maintaining it for many years.

Introduction to Steel Cabinets

A metal container, or cabinet, can be used to store a variety of items in safe and effective condition.The concept is similar but different. These pedestal cabinet are constructed to last in environments in which security, enterprise, and long-term use are essential, as they may be designed to withstand the toughness of touchy files and commercial equipment.

Steel cabinets offer several benefits, starting with:

- Strong and durable against physical injury.

- Fire and corrosion resistance.

- Secure locking mechanisms.

- Easy to clean and maintain.

- Customizable shelving and configurations.

Materials and Construction

The selection of steel for cabinets is based on the intended application, and they are typically constructed from premium steel sheets.

Types of Steel Used:

- The office and commercial sectors rely on cold-rolled metal for its superior pleasantness, smoothness, and precise measurements.

- The electricity of hot-rolled steel is awesome, making it perfect for rugged and commercial settings.

- Stainless steel is favored in regions that include laboratories, kitchens, and outdoor spaces where corrosion can not occur.

- The thickness of metal is generally between zero 7 mm and 2 millimeters.

When used for storage with greater weight, steel of a thicker consistency provides more structural strength and better bearing capacity.

Surface Finishes:

A variety of finishes are commonly employed by manufacturers to improve the steel’s

- strength and beauty

- Powder coating is a long-lasting, chemical-resistant coating that can face up to scratches, rust, and other adverse substances.

- A zinc coating is generally applied to outdoor cabinets, which makes them more proof against corrosion.

- The use of epoxy paint is usually recommended for environments with expanded humidity or chemicals.

Design and Functional Features

Steel cabinets are designed to be both flexible and functional. The design of swinging doors, sliding doors, and open-fronts is determined by the specific application.

Common Features:

- To ensure safety, the door is strengthened and stowed upright.

- Shelves that are flexible and can accommodate a variety of objects.

- Many lock systems are built with these, including basic keyless entry and digital security.

- Chemical storage or moist environments require the use of ventilation holes.

- Hidden drawers for optimal storage and optional extra space.

The ability of stronger models to withstand greater loads is dependent on the anchoring and reinforcement of the frame.

Installation Guidelines

The installation of a steel cabinet is usually effortless if the unit is already built into it. Care must be taken when assembling and positioning larger or flat-packed models.

- InstDetermine the right place: Ensure that the cabinet and its contents suit perfectly at the ground.

- The cupboard ought to be built as consistent with the producer’s instructions, with panels placed and shelves secured securely.

- Mounting the cabinet: For tall or slender devices, it’s advocated to mount the cabinets to a wall or ground to avoid tipping, especially in areas that are liable to heavy use or seismic activity.

- Sorting: Fit drawers, dividers (if required), or custom shelving.

Maintenance Guidelines

Properly maintained metallic mobile pedestal can provide a protracted-lasting answer. Regular maintenance is necessary for the unit’s safety and functionality, and it ought to be maintained frequently.

Weekly or Monthly Tasks:

- Wipe surfaces that might be blanketed with dirt, dust, or chemical substances with a humid fabric and a slight detergent to remove them.

- Evaluate the efficiency of locks and their related components.

- Apply silicone spray or moderate oil to hinges and sliding tracks. Set them easy.

Quarterly Maintenance:

- Secure the screws and bolts’ connections, especially on doors or cabinets which are regularly used.

- Prevent rust from occurring by removing even a minor crack.

- Place shelves where they are placed to ensure even load distribution.

Annual Inspection:

- Observe corrosion, especially in regions with excessive humidity or uncovered to chemicals.

- Properly clean internal surfaces if stored for medical or food purposes.

- Use lock mechanisms to ensure ongoing security measures.

Troubleshooting Common Issues

In case your metallic cupboard is experiencing wear or overall performance problems, there are approaches to fix it.

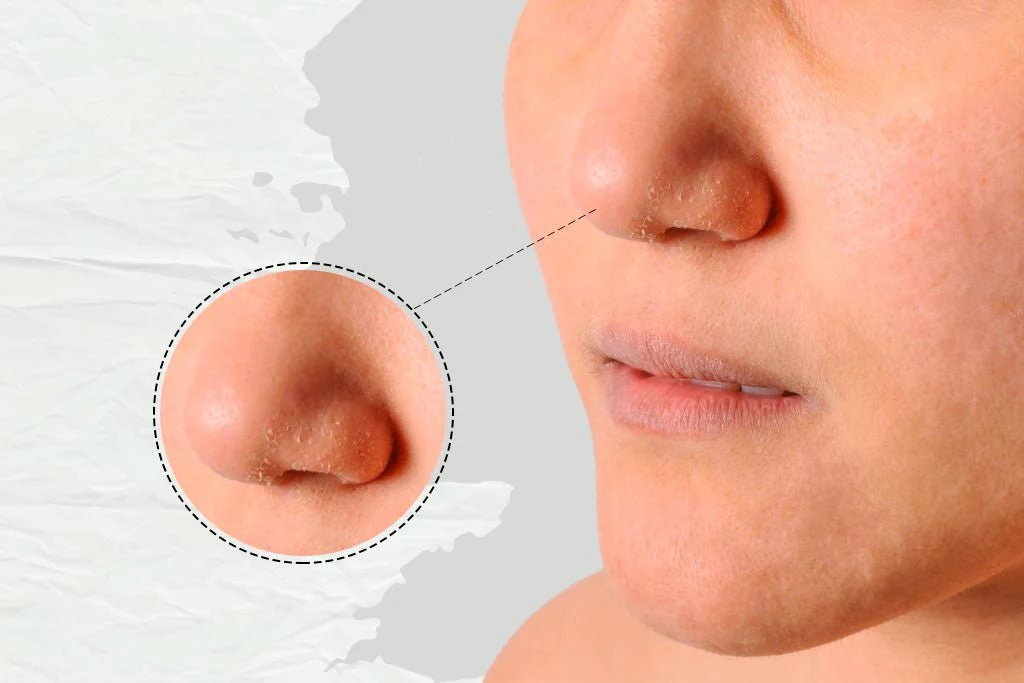

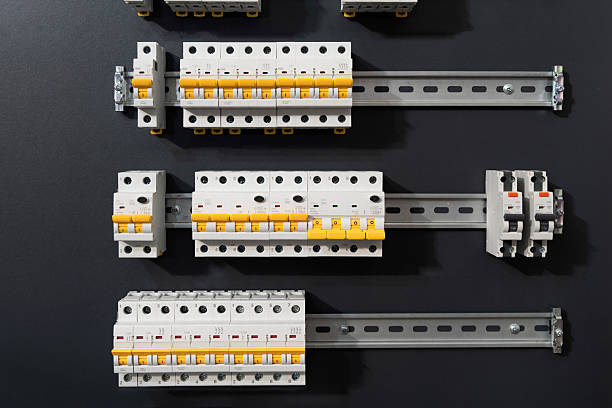

- Uneven flooring or loose hinges: Common reasons for misaligned doors. Smooth out the cabinet and tighten the hardware. (One part is pictured)

- Apply a sanding solution, use a rust converter, and paint the affected area with compatible finishes to remove rusted spots.

- Apply lubricant to worn-out drawers or doors to clean their tracks and hinges. Additionally, avoid sticking them together.

- When experiencing a lock malfunction, it’s recommended to either replace the worn-out lock cylinder or use lubricant.

Should shelf sagging persist, the solution is to either relocate the shelf or install it in a thicker gauge due to persistent overcharging.

Safety Considerations

Safely utilizing a steel cabinet is equally crucial as selecting dependable units. Preventing injuries or structural damage is viable with these safety measures:

- Avoid climbing or standing on the cabinet.

- To save you tipping, it’s really useful to preserve gadgets that are heavier at the lower shelves.

- Mounting tall cabinets can help prevent injuries, particularly in areas in which seismic hobby is in all likelihood to arise.

- Close the cupboard whilst now not in use, especially when you have equipment, chemical substances, or touchy substances.

Environmental and Compliance Factors

Steel is extraordinarily recyclable, and lots of manufacturers now provide more eco-friendly alternatives with recycled coatings and decreased emissions at some stage in manufacturing. Moreover

Ensure that the metal field you operate for risky gadgets meets sure requirements, which include:

- OSHA regulations for workplace safety.

- NFPA fire safety codes.

- ISO quality and environmental standards.

Look for certifications or labels that validate the safety and durability standards of the cabinet.

Choosing the Right Steel Cabinet

Not all steel cabinets are identical. The ideal model should be based on:

Useful for ensuring office and industrial tool storage, chemical safety, and other purposes. Additionally. The level of security in basic lock-and-key systems is inferior to that of more secure locking systems. Determine the total weight of the contents and select your shelves. Ensuring that your space is as close to the wall as possible. For extended journeys, caster wheels are an option.

Conclusion

A metallic cupboard is a critical piece of a garage machine that balances electricity, safety, and durability. Whether you are outfitting a place of work, a lab, or a workshop, expertise the materials, format, and preservation necessities will make sure you get the quality overall performance out of your investment.

With the right setup, ordinary cleansing, and well-timed upkeep, your steel cabinet will provide a stable and green garage for decades.

Always follow producer guidelines, safety requirements, and environmental practices to maximize the fee and lifespan of your cabinet.