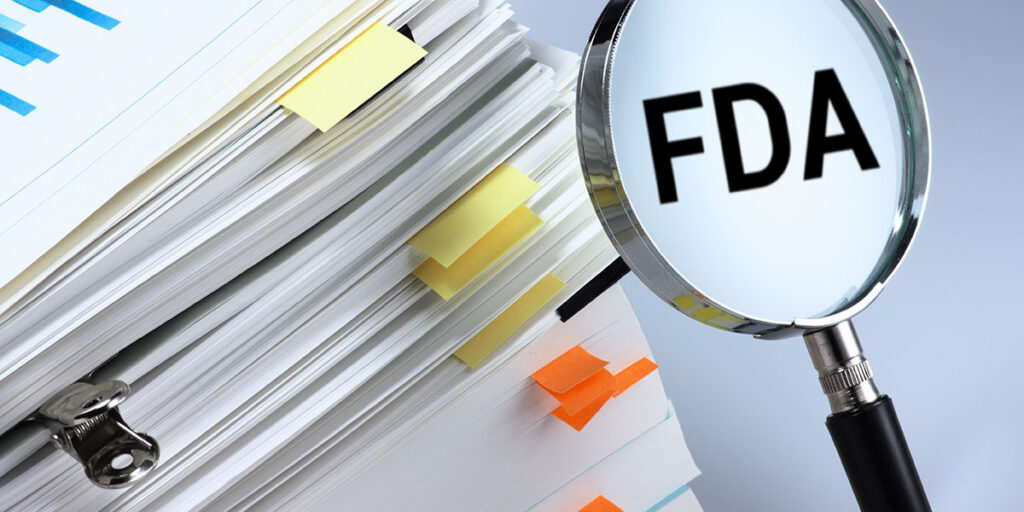

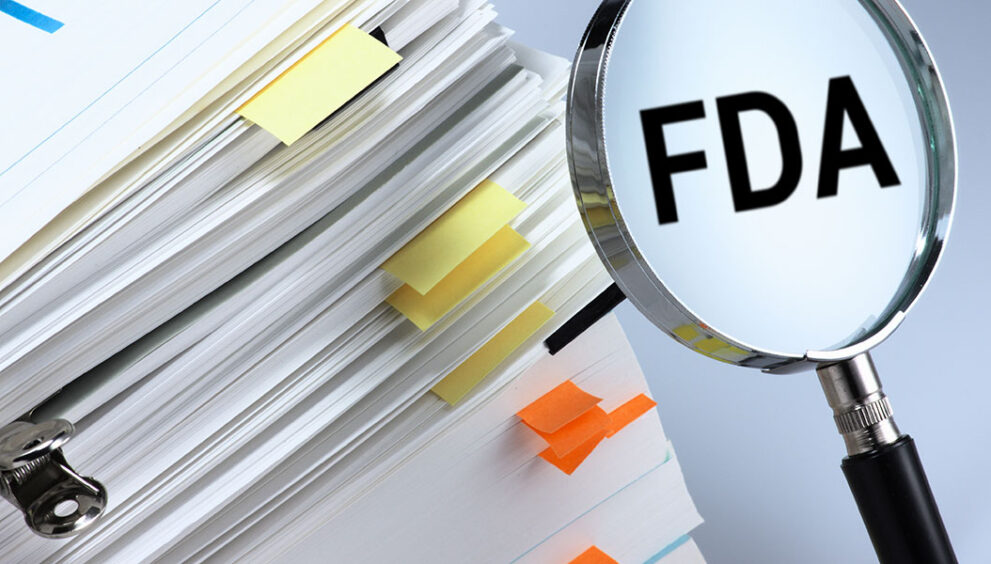

What You Can Learn from Jamie R Thompson’s FDA Inspection Patterns

When an FDA inspector walks through your doors, they’re not just looking for “compliance in general.” Each inspector brings their own experience, focus areas, and patterns to the table, and that can make the difference between a smooth inspection and a string of citations.

One name you may have come across if you work in pharmaceutical or biologics manufacturing is Jamie R Thompson. Thompson is a well-established FDA investigator known for his meticulous inspections and frequent findings in certain areas of GMP compliance.

Here’s the thing: if you can anticipate what an inspector like Thompson tends to look for, you can prioritize the right corrective actions before they even show up at your facility.

Here, we’ll break down inspection patterns of Jamie R Thompson FDA, the most frequent citations he issues, and what your team can do to prepare smarter.

Who Is Jamie R Thompson?

Jamie R Thompson is a senior FDA field investigator with years of experience conducting inspections at pharmaceutical, biologics, and sterile drug manufacturing facilities across the United States. His inspection record shows a particular focus on high-risk operations — sterile manufacturing environments, API (Active Pharmaceutical Ingredient) production, and biologics facilities where control over contamination and data is paramount.

Public FDA records indicate that Thompson is among the more active investigators in the field:

- He consistently inspects dozens of facilities each year, with concentrations in the Northeast and Midwest regions.

- His inspections are often assigned to sterile, aseptic, or otherwise high-risk operations, where regulatory scrutiny is naturally more intense.

The volume of Form 483 observations issued by Jamie R Thompson, places him among the more active and thorough investigators in the field, making his inspection style and focus areas highly relevant for any site operating in these regulated industries.

What the Data Shows: Frequency, Focus, and Findings

Analysis of FDA inspection records reveals that Jamie R Thompson:

- Inspects dozens of facilities per year, particularly in the Northeast and Midwest regions.

- It is frequently assigned to manufacturers with sterile or high-risk operations, where regulatory scrutiny is naturally higher.

- Issues a higher-than-average number of Form 483 observations per inspection, reflecting a thorough and detail-oriented approach.

These are more than trivia. They’re early warning signs of where you and your team need to focus when preparing for an inspection by Thompson or an inspector with a similar profile.

Top 5 Issues Jamie R Thompson Cites Most Often

When you review Thompson’s past inspections, certain GMP lapses show up again and again. Here are the most common:

- Inadequate Documentation

Time and again, Thompson has flagged:

- Incomplete or inconsistent batch records

- SOPs that don’t align with what actually happens on the floor

- Weak change control documentation, with missing justifications or approvals

Documentation isn’t just a formality to him; it’s a window into whether your processes are actually under control.

- Environmental Monitoring Deficiencies

One of his hallmarks is scrutinizing how well aseptic and cleanroom environments are monitored. He’s cited:

- Inadequate sampling plans or frequencies

- Missing trending of microbial and particulate data

- Unclear or undefined alert/action limits

Facilities with otherwise well-run operations have still been dinged for treating monitoring as a checkbox rather than a proactive tool.

- Data Integrity Concerns

Thompson’s inspections align with the FDA’s growing emphasis on data integrity. Frequent findings include:

- Missing or incomplete audit trails in electronic systems

- Uncontrolled or unvalidated spreadsheets in QC labs

- Lack of restricted access to critical systems

- Inability to show who made changes to records or why

For regulated industries, these issues go beyond IT; they strike at the credibility of your entire quality system.

- Personnel Training Gaps

Even with advanced equipment and good SOPs, untrained personnel undermine compliance. Thompson has cited facilities for:

- Failure to document periodic retraining

- Operators deviating from aseptic techniques in cleanrooms

- Supervisors are unable to describe their responsibilities clearly during interviews

This is why training needs to go beyond orientation, and why your people need to feel confident answering questions on the spot.

- Weak CAPA Programs

Thompson often identifies superficial or incomplete corrective and preventive actions. Common gaps include:

- Investigations that fail to identify true root causes

- CAPAs that address symptoms instead of systemic problems

- No follow-up to verify that corrective actions were effective

If you can’t show your CAPA program works, it signals a reactive, not proactive, quality culture.

These findings point to something larger: Thompson expects a culture of quality, not just documented procedures. He looks for evidence that your systems are alive and effective, not simply written down.

How You Can Use This Insight

Now that you know what this particular investigator tends to prioritize, how can your team put that knowledge to work?

Here are a few practical steps:

- Run targeted internal audits: Assess your facility specifically against the five areas above, and close gaps before inspection.

- Conduct mock inspections: Have your QA team role-play with these high-frequency citations in mind, to build muscle memory.

- Benchmark against industry peers: Use public FDA data to see how similar facilities fare, and measure your risk posture.

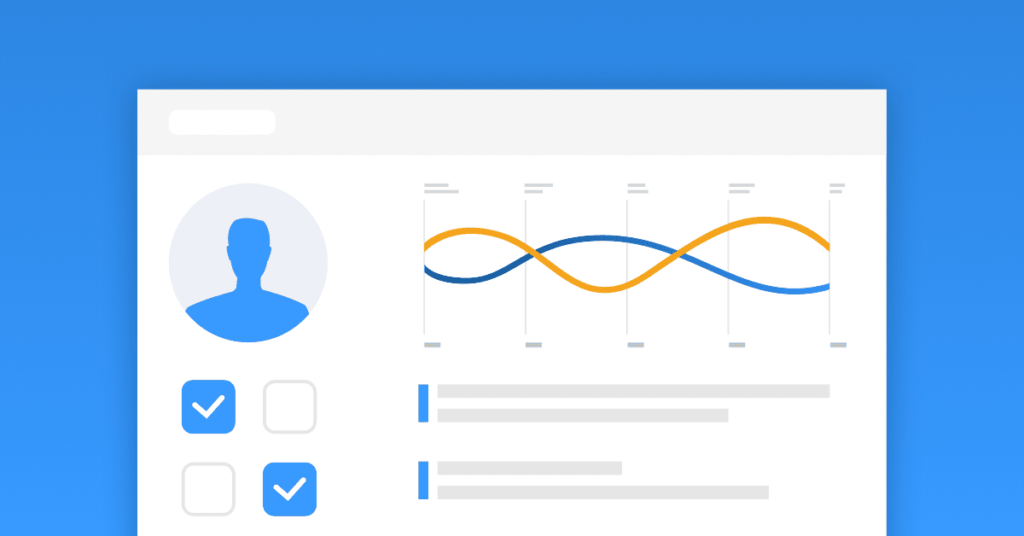

- Leverage regulatory intelligence tools: Platforms like Atlas Compliance help you drill into inspector-level profiles, track trends over time, and receive proactive alerts as new inspection data comes in.

Why Inspector Patterns Are Just the Start

One final note: inspector patterns are incredibly useful, but they aren’t static. FDA investigators rotate assignments, and even the most experienced adapt their priorities over time as regulations and guidance evolve.

That’s why you shouldn’t rely on anecdotal experience alone. You need a systematic way to track patterns across inspectors and regions and stay up to date with real-time enforcement data.

Atlas Compliance gives you just that:

- Inspector-level profiles with documented patterns

- Facility benchmarking and risk scoring

- AI-driven analysis to recommend focus areas

- Alerts and reports to keep you informed as regulations shift

Conclusion

Not all FDA inspectors approach GMP issues the same way, and recognizing those differences can give your team an advantage. Jamie R Thompson is particularly active in sterile, biologics, and API inspections, with frequent findings in documentation, environmental monitoring, data integrity, training, and CAPA. By studying patterns from Jamie R Thompson inspections, you can identify vulnerabilities and prioritize the right fixes before they’re flagged.