Comparing Oak and Maple: Adapting Your Sanding Method to Vary Wood Hardness

When it comes to hardwood floors, both oak and maple are top choices for homeowners who value strength, style, and longevity. Yet while they may seem similar at first glance, these two types of wood behave very differently under sanding tools. Each has its own level of hardness, grain pattern, and finishing requirements, which means your sanding approach should be carefully adapted to suit the wood you’re working with. Learning about these differences is vital if you desire to attain an even, smooth, and professional-looking finish that brings out the natural beauty of your floor. At Alpha Floor Sanding they only produce quality finishes. Located in London but serving the wider area including Croydon, you will not find a more professional and reliable floor sanding company.

Oak: The Classic Choice for Character and Ease of Sanding

Oak is a popular hardwood used for flooring, adored for its classic look and dense grain texture. It comes in two principal types: red oak and white oak, which are both strong and have a natural warmth.

Why oak is a top pick with professionals is its moderate hardness. It’s hardy enough to handle heavy use but not so hard that sanding is a real chore. On the Janka hardness test—a benchmark for determining wood strength—red oak measures about 1,290, white oak a tick harder at 1,360.

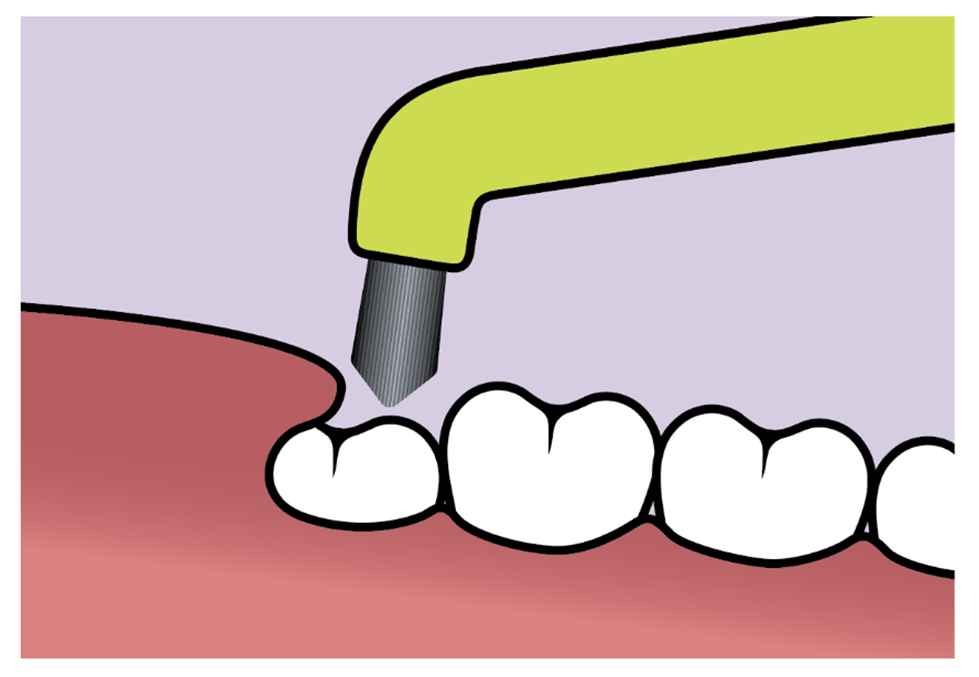

This hardness level makes it possible for sanding machines to strip off existing finishes and scratches effectively without burning or glazing the surface. Oak’s open grain structure also makes it receptive to varying grit sequences, making it less complicated to develop an even texture. Professionals will typically begin with a coarse grit (about 36–40) to strip off old coatings, followed by medium and fine grits (up to 100–120) for a level finish.

Since oak picks up stains evenly, it is also forgiving for newbies. Once sanded to a finish, the surface absorbs finishes nicely, accentuating its natural grain and colour variations.

Maple: The Harder Challenge with a Rewarding Finish

Maple, however, is characterised by its firm, close grain and increased hardness. Depending on the type, its Janka rating can be anywhere from 1,450 up to over 1,800, which makes it much harder than oak. While making maple very durable, this also makes it unusually challenging to sand.

The first observation about maple is its fine grain and smooth texture, which is prone to revealing flaws if the sanding process is not carefully executed. Irregular pressure, flat sandpaper, or skipping grits can produce noticeable scratches or burn marks that are apparent after the finish has been applied.

They usually work on maple with added patience and care. Applying fresh, sharp sandpaper and keeping a consistent stroke is important not to overheat the surface. Rather than beginning with too coarse a grit, masters usually start from a medium one (about 50–60) to minimise the chance of causing deep scratches, then move gradually through progressively finer grits to 120 or even 150 for an extremely fine surface.

Since maple’s close grain won’t stain uniformly, pre-conditioning or applying a sanding sealer prior to finishing produces an even look. A deliberate, systematic process for sanding and staining yields a smooth, refined finish that optimises maple’s own brightness.

Sanding for Various Levels of Hardness

The largest contributor that differentiates oak and maple is their reaction to sanding pressure and heat. Oak’s open pores permit easier dust removal and cooling while sanding, but maple’s density results in friction heating up more quickly—increasing the likelihood of burning or glazing.

When using oak, a regular rotary or drum sander is effective, and you can sand at a reasonable speed with no problems. With maple, though, it’s best to cut less pressure and travel slower to avoid generating too much heat. Keeping sandpaper clean and also replacing it frequently maintains a consistent cut.

Corners and edges are best controlled with an orbital or detail sander. Maple, being less tolerant, also needs more hand sanding in restrictive areas to ensure the surface is even. Oak, however, can stand a rougher edge sanding without marks.

Dust management also plays a role in achieving a fine finish. Since maple produces finer dust that can clog the surface, using a vacuum-assisted sander helps maintain efficiency and prevents particles from scratching the wood during the process.

Finishing Techniques to Match Each Wood Type

After sanding is finished, the finishing phase brings out the character of the wood and defends it for the long term. The open grain of oak is perfect for staining since it absorbs colour easily and creates high contrast. Dark walnut or light natural finish, oak provides deep visual richness with ease.

Maple, though, demands a more managed process. Since it resists deep penetration, inconsistent staining can leave blotchy spots. Applying a pre-stain conditioner or employing clear finishes such as polyurethane, oil, or natural wax tends to fix the problem. These finishes enhance maple’s creamy undertones and smooth surface while maintaining its clean, modern look.

Both woods could use a topcoat that is long-lasting, which provides protection from moisture, scratches, and everyday wear. Water-based polyurethane provides a tough finish without yellowing in high-traffic zones.

Why Professional Expertise Makes a Difference

While sanding can be attempted by homeowners, the variation in hardness between maple and oak makes professional help a smart option. Pros know how to adjust machines, pressure, and grit progressions to specific types of wood. Their accuracy ensures that the surface is kept smooth, even, and ready for a perfect finish.

Sanding with professionals also avoids permanent errors like over-sanding, which lightens the wood surface and decreases the lifetime of the floor. With experienced professionals, you can get uniform outcomes and a finish that boosts your home’s worth and beauty.

No hardwood floors are the same, and knowing how to modify your sanding technique to the hardness of the wood is the key to maintaining its beauty. Oak’s tolerance and dramatic grain make it a perfect choice for rich, personality-packed finishes, and maple’s smooth density provides a clean, contemporary appearance when treated gently. By recognising the unique sanding needs of each species—and trusting the process to skilled professionals—you ensure that your floors remain smooth, resilient, and visually stunning for years to come. Whether you’re reviving an old oak floor or refining the shine of maple, the right sanding approach is the foundation of lasting elegance.