Choosing Custom Jewelry Makers for Exclusive Brand Lines

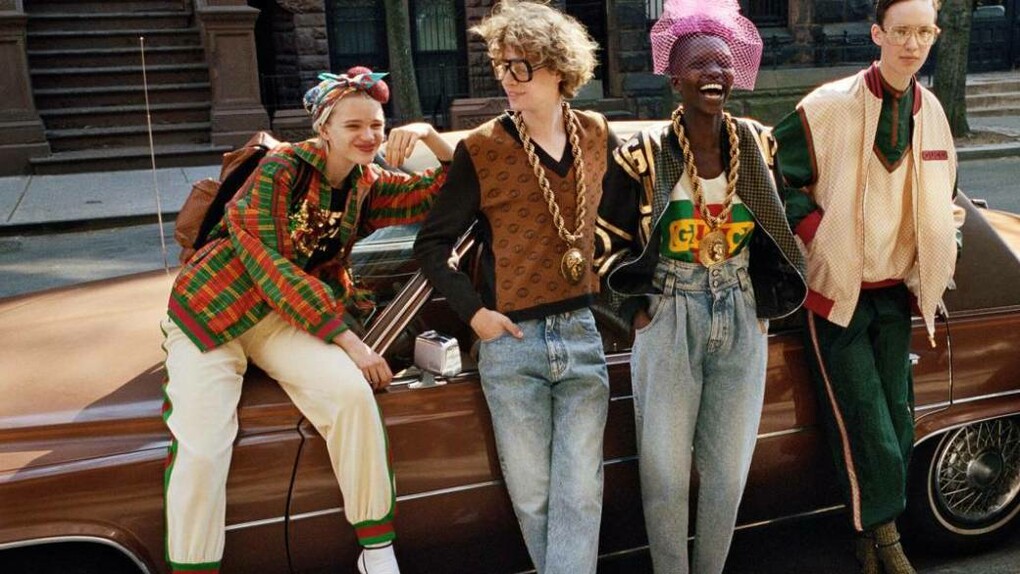

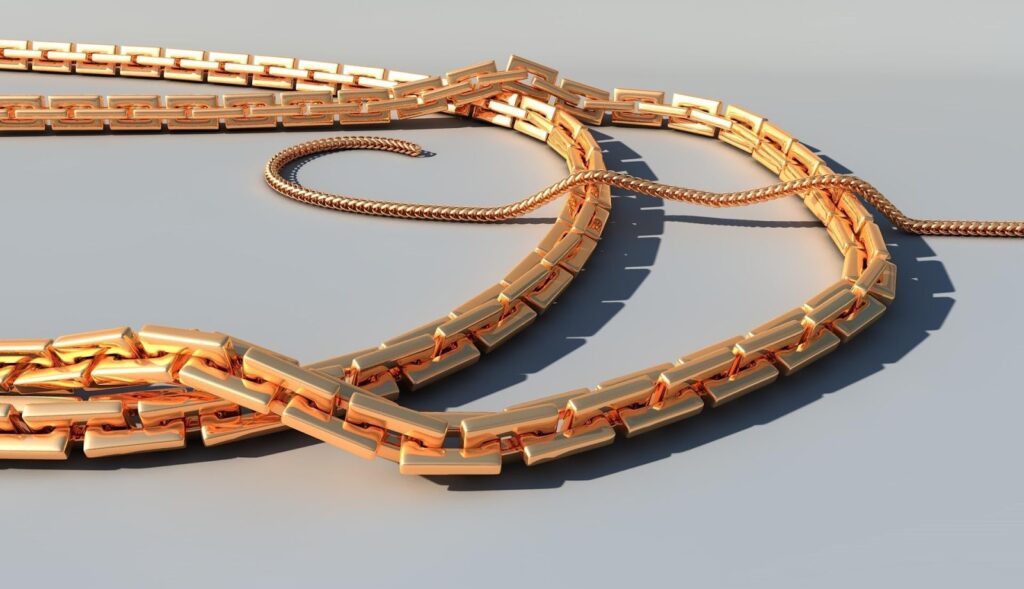

Fashion and accessories are among the most competitive sectors of the business world. For B2B businesses, working with custom jewelry makers and wholesale jewelry manufacturers is the key to building impressive collections. For high-impact collections, choosing the right collection partner allows for quality, punctuality, and unique designs that help distinguish a brand.

The extensive scope of this piece is tailored to practical B2B customization queries.

Determine Collection Target and Brand Mission

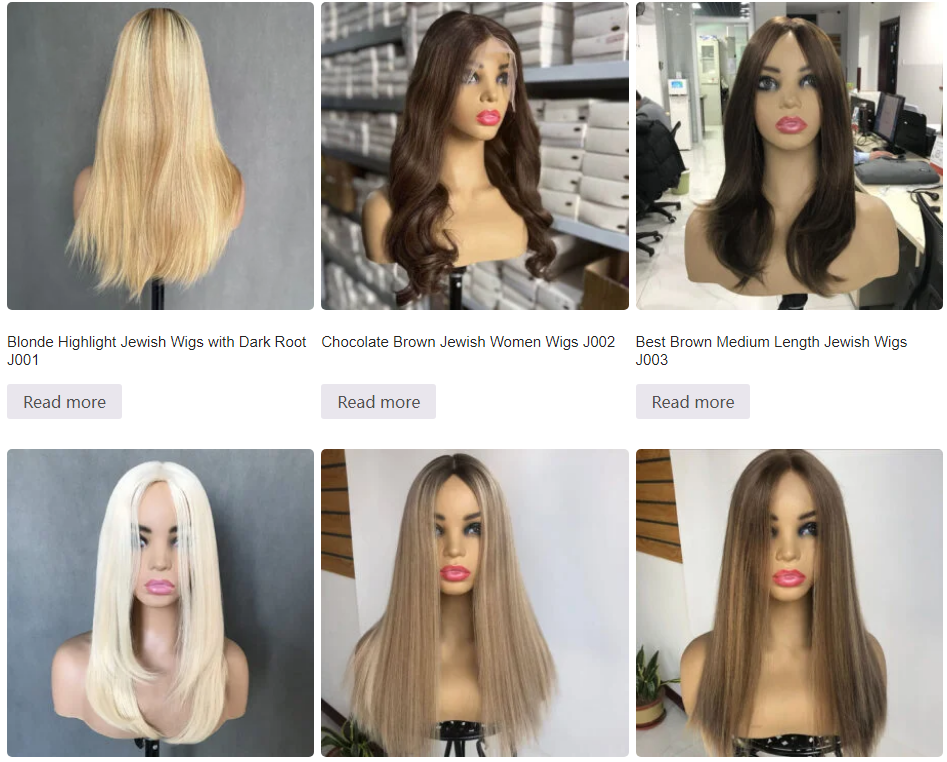

The foremost thing to sort out with a custom jewelry maker is the target brand mission and collection goals. Audience, budget, and general style are non-negotiable. Will it be high-end extravagance, artistic mainstream, or sustainable collections? These will point to the wholesaling level of certain jewelry manufacturers.

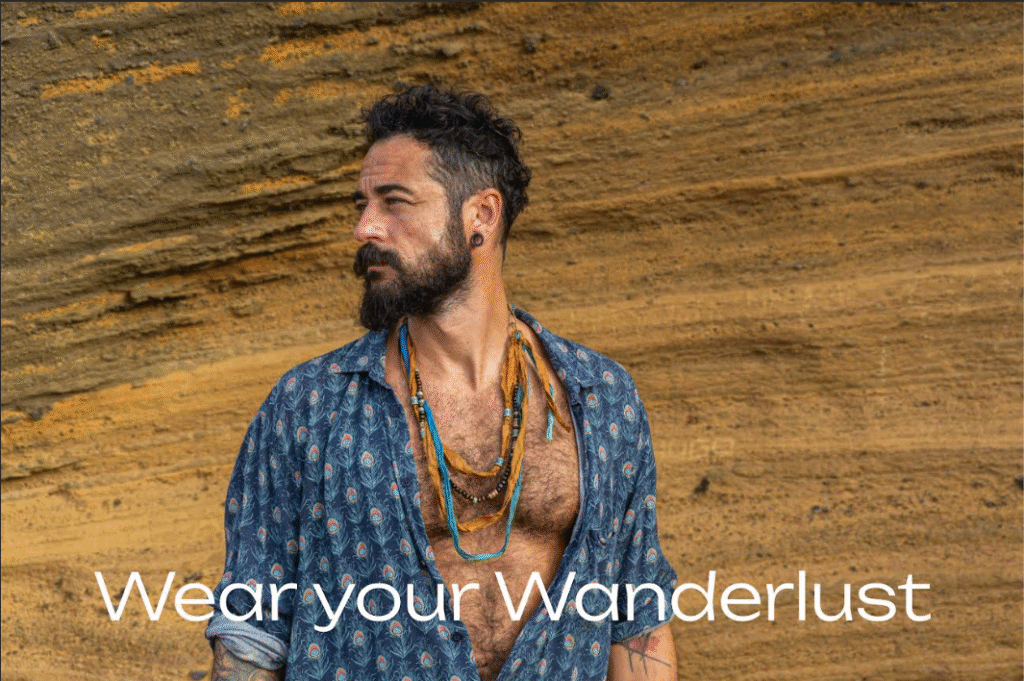

Design complexity, preferred materials, and the extent of personalization are all relevant factors. Some artists work primarily with metals like stainless steel or silver, and some with lower-cost mixed or plated designs. Understanding these details helps narrow options, enabling filtering potential partners who can provide pieces that match your brand.

Knowing the brand focus also helps determine collection scope. Some manufacturers focus on producing pieces that lean towards the fast-fashion sphere, while others work on slow-fashion. Prioritization should center on which strategy aligns with your brand’s long-term vision.

Evaluate the Capability of Proposals and the Level of Innovation

A top tier custom jewelry maker should not merely be thought of as an outsourcing company; they should provide the creative partnership you and your brand need. B2B companies need to work with manufacturers who understand design and innovation. Look to those who provide 3D modelling, prototype, and sample production, as this is an essential step to making sure that your designs become products ready to launch in the market.

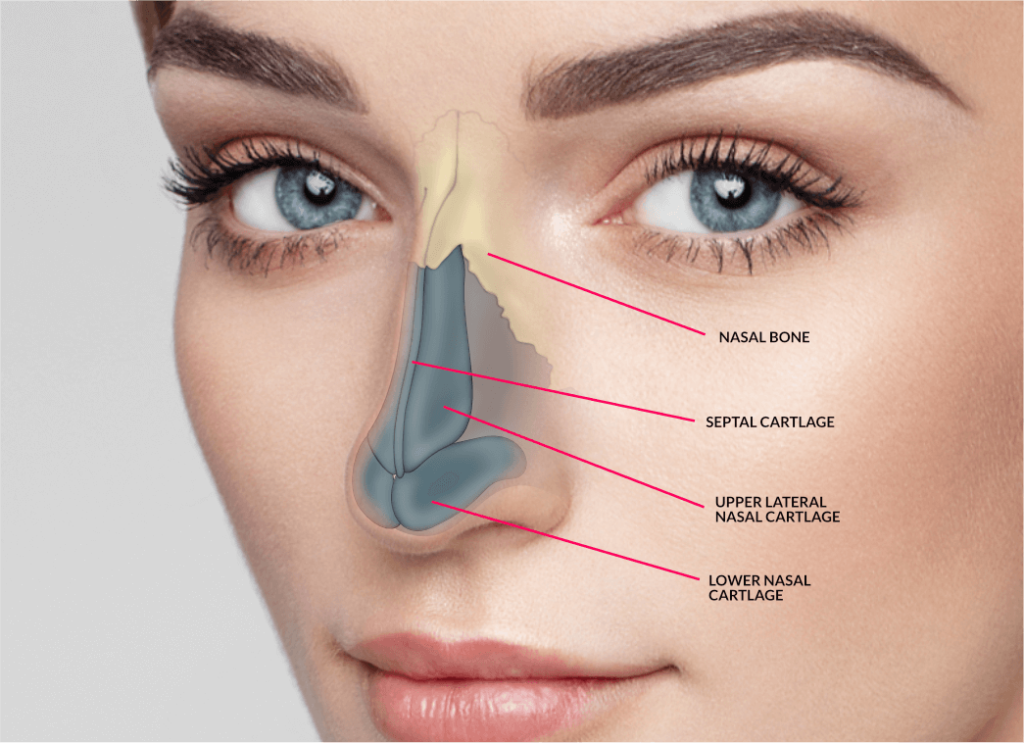

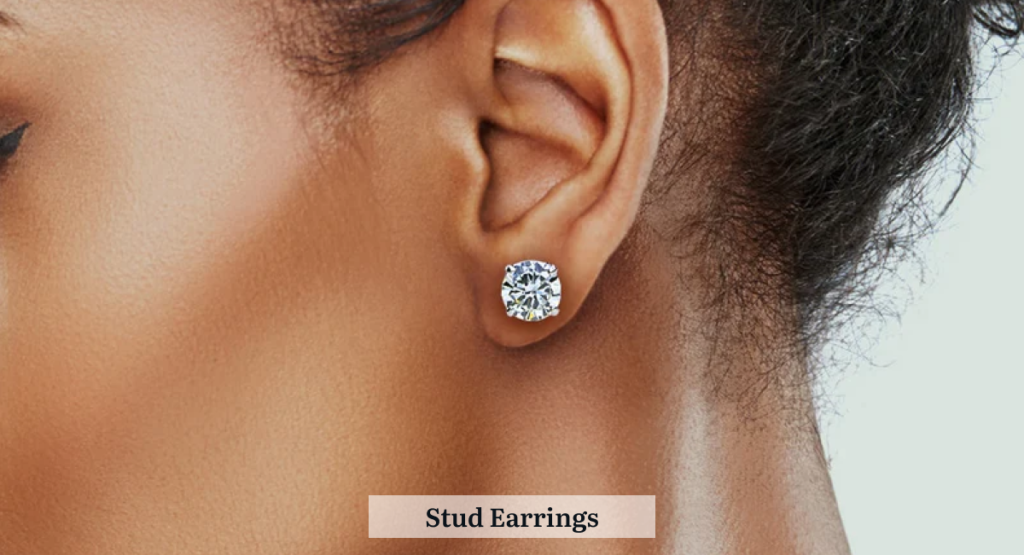

Design teams at manufacturing companies can help choose materials, methods, and identify the most recent trends within the market. For example, the crafting of brass, silver, and stainless steel jewelry takes varying techniques and levels of detail. Understanding various materials gives the manufacturer the best chance at accurately understanding and fulfilling your vision.

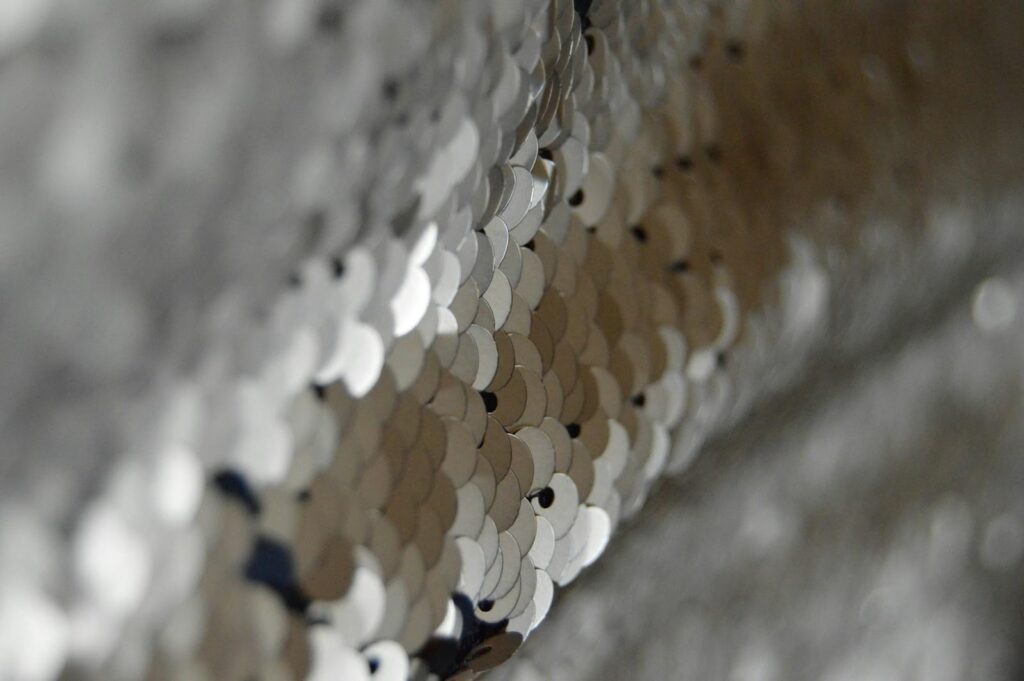

The ability to innovate must also include the creation of new textures, finishes, and design structures. For B2B enterprises, having a collaborator suggest new ideas or different options regarding your designs greatly benefits the overall B2B value. Looking at a manufacturer’s portfolio or case studies can help to understand their range and their ability to design distinct and cutting-edge items.

Quality and Material Sourcing Should Be a Priority

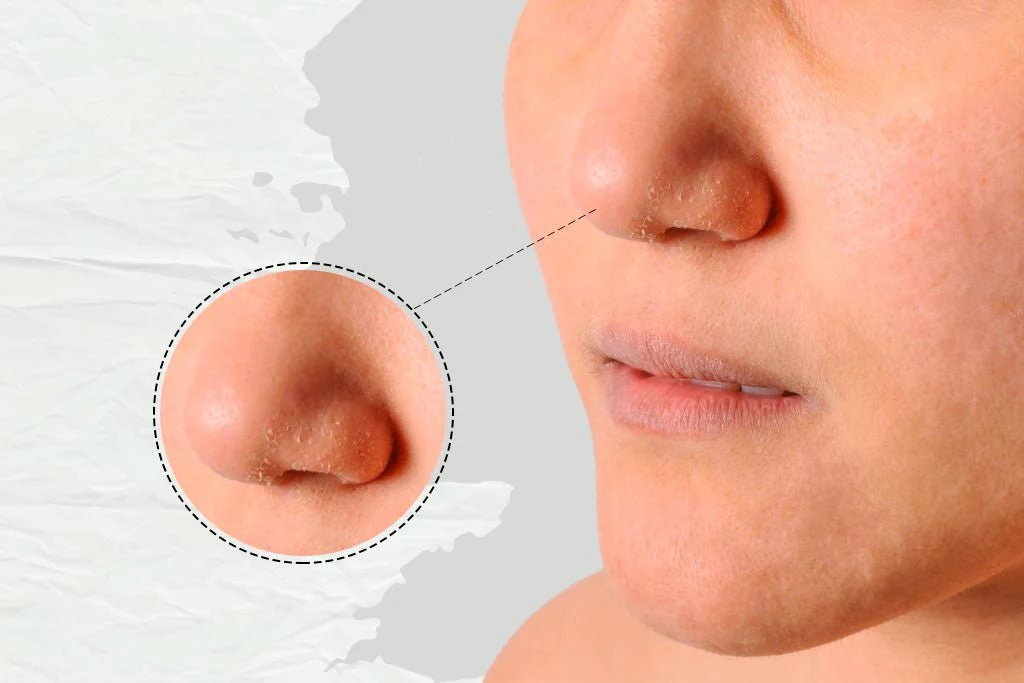

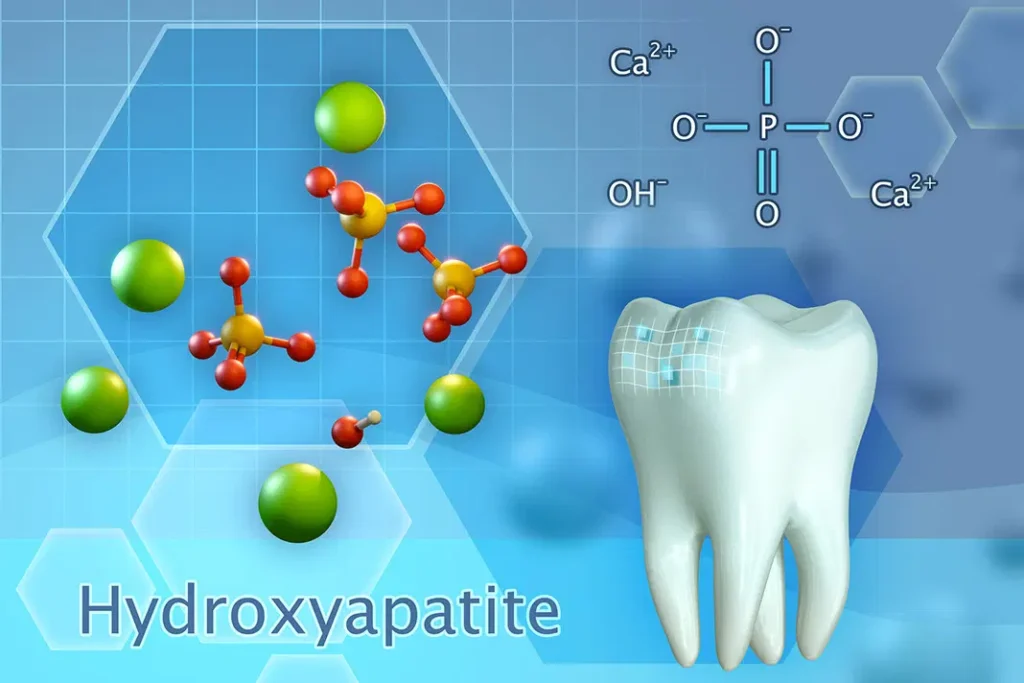

In B2B jewelry production, the self-consistency and the quality of the production are of utmost importance. A B2B jewelry manufacturer must show the customer that they understand the importance of quality control by showing control over the whole process, from the acquisition of the raw materials to the packaging process at the end. The presence of different Certifications proves that the manufacturer meets important criteria, such as durability, safety, and quality control at the international level. Certification examples include REACH, GRS, and SGS.

So is material sourcing. Global customers now expect metals that are ethical, hypoallergenic, recycled, or even all three. Nickel-free, cadmium-free, and lead-free metals not only satisfy safety requirements and sustainable eco-friendly metal works but also promote positive brand equity. Discussing sourcing strategies with your maker allows your collection to be produced ethically and responsibly.

Closely monitoring finishing techniques, reviewing plating, and examining defect rates also guarantee that your products are well made. Excellent manufacturers perform numerous quality checks and maintain low defect rates, usually less than 3%. This kind of dependability, especially with B2B brands, minimizes returns and boosts customer trust and brand reliability.

In addition, the manufacturer’s capabilities in detail finishing, plating that lasts, engraving, and the security of the stone are very important. Premium products are usually measured by these and the perceived value of your collections increase.

Look at Production Capacity and Lead Times

B2B operations require the highest efficiency possible. When choosing a custom jewelry maker, lead times and production capacity are very important. Understanding a manufacturer’s ability to do small scale sampling and big volume production determines whether your inventory and product launches are on schedule.

Define minimum order quantities (MOQs), monthly output capabilities, and average lead times for production. Some manufacturers specialize in low-MOQ runs that are ideal for limited-edition collections, while others are best suited for high-volume production for retail and wholesale distribution. Considering these variables will prevent supply chain blockages and assist operational planning and its predictability.

Lead time reliability is critical. Trustworthy manufacturers give transparency regarding the production stages, including time frames for prototypes, sampling, and full production runs. Predictable timing is essential for B2B firms as it offers the ability to perform proper inventory control and keeps customers happy. Trusted partners also allow you to plan for seasonally elastic demand and promotional offers.

Assess the Quality of Communication and Support Offered

Excellent communication and support for one another are the pillars of any successful B2B relationship. Quick and direct contact to a custom jewelry maker means that any potential problems are sorted out before they grow big and lead to production delays. It is also essential to have uninterrupted contact throughout the design and production phases to mitigate costly misunderstandings.

Support beyond order production can include value-added services that improve your collections and strengthen your market position. More services include branded grade design and production packaging. For example, branded packaging can strengthen the customer’s experience and increase the product’s perceived value.

B2B businesses also gain from manufacturers who collaborate with them through understanding the market, suggesting suitable materials, and offering insight on trends. Such teamwork guarantees that your collections are technically innovative, commercially fit, and competitive. Strong after-sales service, such as quality assurance, polite requests, and defect resolution, builds trust and keeps a partnership alive.

Conclusion

Selecting the best jewelry manufacturers should also be a considered decision. The quality, uniqueness, and overall success of your brand collections depend on it. B2B businesses should look for custom jewelry makers who align with the brand’s vision and evaluate them by design capability, materials, production speed, and communication. This will ensure your company meets the creative and commercial goals.

A good manufacturer does not just make quality jewelry; they innovate and expand the brand with the manufacturer as a business partner. This empowers B2B businesses to keep offering branded collections that are competitive and of good quality to increase the market demand and brand reputation. Well-chosen partnerships make sure your collections reflect your brand and are quality pieces.

Through these principles, B2B brands can produce striking, sustainable, and market-ready jewelry collections that maintain client value, increase sales, and achieve success over time, establishing a firm position in the competitive jewelry market.