Who Is Brittany McCracken? Overview of Her Role as an FDA Investigator

When the FDA arrives for an inspection, it rarely comes unannounced. But what often surprises companies is who the investigator is and what they’ll zero in on. Every FDA investigator brings their own experience, areas of focus, and inspection style, all of which can influence the outcome.

One name worth knowing is Brittany McCracken. With more than a dozen documented inspections across biotech, medical devices, and precision manufacturing, she’s quickly becoming a familiar presence in FDA-regulated industries.

If your company operates in her territory or falls within the sectors she frequently audits, knowing her tendencies and priorities can help you prepare smarter, reduce your risk of formal observations, and engage more effectively when it counts. Let’s take a closer look at her inspection history, what it reveals about her approach, and why it matters for your compliance strategy.

Who Is Brittany McCracken? An Introduction

Brittany McCracken is a U.S. FDA investigator who has conducted at least 13 documented inspections in recent years, primarily focusing on medical device manufacturers, biotech firms, and highly regulated precision manufacturing facilities.

Her work is part of the FDA’s broader mission to ensure that all regulated products meet stringent quality, safety, and efficacy standards in line with Good Manufacturing Practices (GMP) and other applicable regulations.

Since at least 2023, she has been active in FDA field operations, and her inspections so far paint the picture of a diligent, methodical investigator who holds companies to a high standard, yet seems to prioritize corrective action over punitive measures.

A Closer Look at Her Inspection Record

McCracken’s inspections cover a mix of small precision-manufacturing firms and larger biotech players, mostly concentrated in the California Bay Area.

Key Data Points

- Total inspections: 13

- Form 483s issued: 8

- Warning Letters issued: 0

- Inspection duration: Between 3 and 15 days, averaging ~6.5 days

- Inspection years: Active from at least 2023 through 2025

- Primary geography: California Bay Area (Sunnyvale, Fremont, San Jose, Milpitas, etc.)

What stands out in her record is that roughly 60% of her inspections result in a Form 483. This indicates a thorough level of scrutiny — she doesn’t hesitate to identify and document deficiencies — but the absence of Warning Letters suggests that she gives companies room to correct their mistakes before escalating.

For QA and Regulatory Affairs teams, this signals both opportunity and risk: you’ll want to be ready to demonstrate not just compliance, but a willingness and ability to fix issues proactively when they’re pointed out.

What Her Inspection Record Tells Us About Her Style

So what can we infer from McCracken’s inspection history? A few key themes emerge:

- Thorough but Corrective

McCracken seems to strike a balance between vigilance and fairness. While she has issued Form 483s in a majority of her audits, none of her inspections have escalated to a Warning Letter. This suggests she works with firms to address deficiencies before recommending further enforcement.

For companies, this is a critical window: if they identify gaps, address them swiftly and thoroughly to avoid further action.

- Focus on Core GMP Principles

Although her inspections have covered a diverse range of facilities, the types of observations she’s issued indicate a focus on fundamentals such as:

- Process controls and recordkeeping

- Equipment validation and ongoing calibration

- Supplier qualification and oversight

- Data integrity in laboratory and production records

These areas are perennially high on the FDA’s radar, and McCracken seems to ensure companies are meeting expectations here before moving on to more nuanced issues.

- Willingness to Dig Deep

Her inspections have varied significantly in length, from as short as three days to as long as two full weeks, which implies she adjusts her depth of inquiry depending on the complexity and risk profile of the operation.

In other words, if your processes are intricate or involve novel technologies, expect her to spend the time it takes to fully understand and evaluate your systems.

Why Your Team Should Care

If your company operates in a regulated sector and particularly in her geographic region, you should assume there’s a chance she (or someone with a similar pattern) will inspect your facility.

For regulatory affairs and QA teams, this knowledge is actionable:

- You can benchmark against the types of observations she has issued in similar facilities.

- You can adjust your internal audit scope to include specific areas she tends to cite.

- You can train your staff to respond appropriately during inspections.

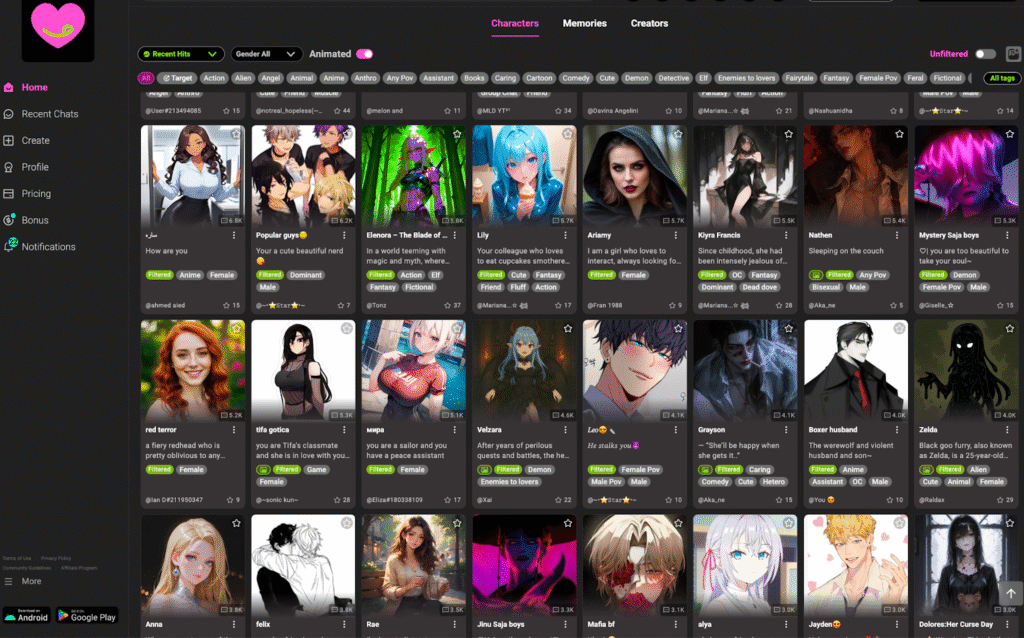

These are exactly the kinds of insights tools like Atlas Compliance AI are designed to surface, making investigator-level data meaningful and practical for your team.

How to Prepare for an FDA Inspection from Someone Like McCracken

Here’s a step-by-step checklist for readiness:

- Keep documentation current and organized. Calibration logs, SOPs, batch records, deviation reports — make sure they’re easy to retrieve and up to date.

- Run regular mock inspections. Simulate FDA-level scrutiny and address findings promptly.

- Fix recurring weak spots. Quality controls, CAPA documentation, and supplier oversight are common 483 triggers — audit these rigorously.

- Train staff on inspection conduct. Everyone should know how to communicate, handle document requests, and maintain professionalism.

- Track industry trends. If the same issues keep surfacing in your sector or among your peers, resolve them proactively before the FDA points them out.

The Value of Investigator Data

FDA investigators aren’t interchangeable. They develop patterns, preferences, and areas of expertise over time, and savvy companies can use that data to prepare more effectively.

By studying investigator-level trends, your team can:

- Anticipate which systems and processes will be under scrutiny

- Design targeted corrective and preventive actions (CAPAs) in advance

- Respond faster and more confidently if a Form 483 is issued

This is where tools like Atlas Compliance AI come in handy, giving you access to actionable insights about specific inspectors and their inspection records.

Conclusion

Brittany McCracken is one of many FDA investigators tasked with ensuring that regulated industries meet their obligations to protect public health. Her track record shows her to be diligent, thorough, and constructive, someone who identifies gaps and expects companies to take responsibility for fixing them promptly.

For firms operating in her territory or industries, paying attention to her patterns isn’t just good intelligence, it’s smart compliance management. The better prepared you are for the kind of inspection she conducts, the less disruptive the process will be, and the more confident you can be in your compliance posture.