Behind the Scenes: How Hardware Manufacturers Are Innovating in 2025

The hardware sector is dynamic in nature and in 2025, innovation has become the center of the stage. Manufacturers of hardware are shoving the envelope with top of the line technologies, eco-friendly solutions, and innovative ideas of design that are not only evolving our vision of home improvement and especially when it comes to custom cabinet hardware. Between clever solutions and eco-friendly materials, the manufacturers come up with new trends that would not only create a higher level of functionality, but also a better look.

The article will discuss the new strategies that the hardware manufacturers are implementing in the future 2025 and how they will change the landscape of custom hardware cabinets. If we look at the recent changes and novelties in this constantly growing industry, what would happen?

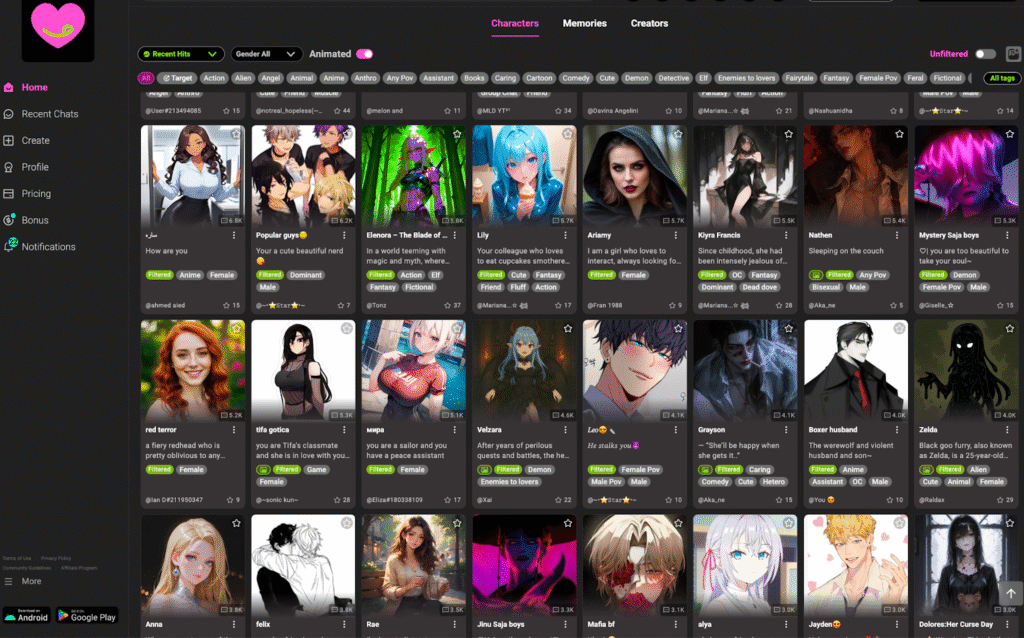

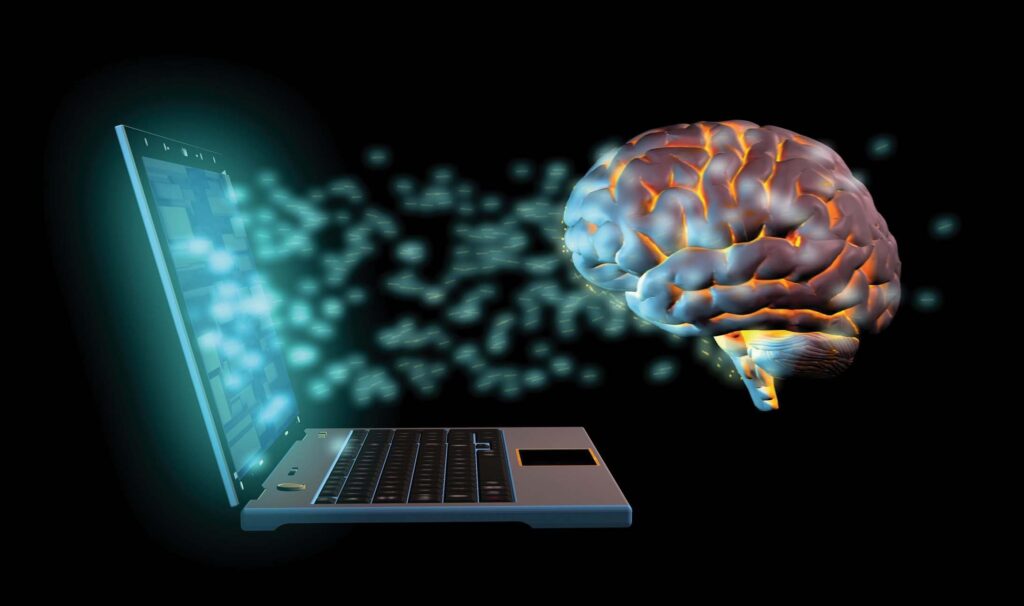

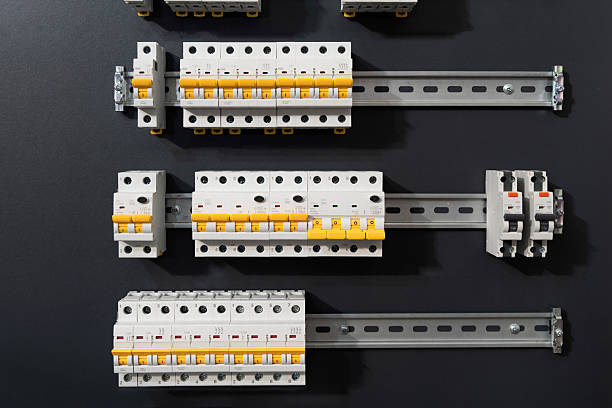

The Rise of Smart Cabinet Hardware

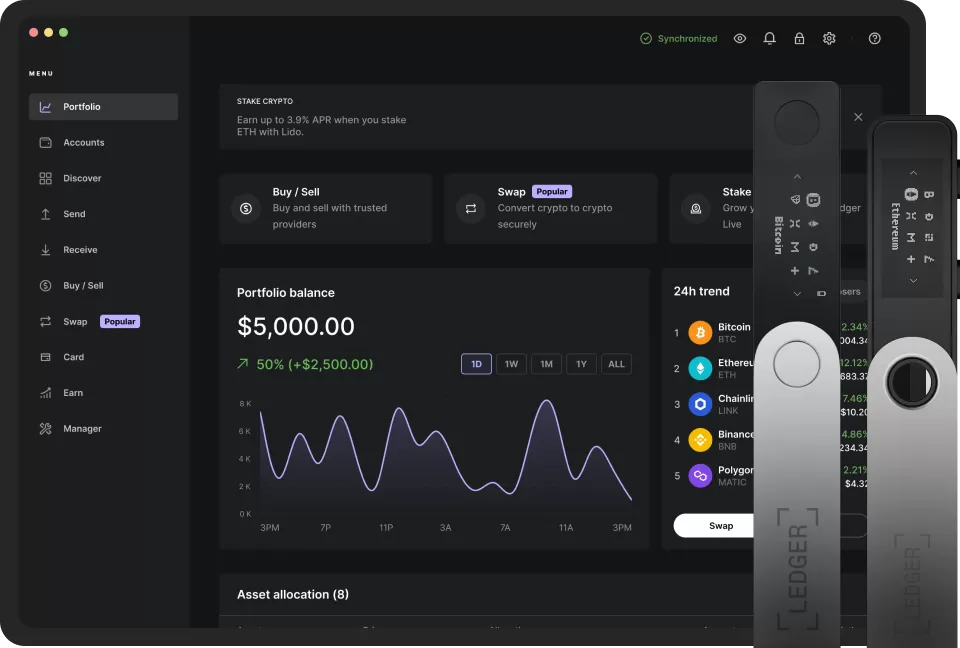

The subsequent technological improvement makes the concept of adding smart technology to ordinary items even more popular. Custom cabinet hardware is not an exception to it in 2025. Smart cabinet solutions: Manufacturers of hardware are now coming up with solutions that are smart, offering more functionality and convenience. Just imagine, cabinets with light handles, and drawers that will automatically open by pushing a button.

Intelligent hardware will also be seen as far as security. To ensure keyless entry, manufacturers are mounting biometric sensors into the handles of cabinets, which is ideal in high-security locations such as kitchens or offices. These inventions are not only convenient, but they also offer homeowners and businesses a modern and a high-tech alternative to all their cabinet hardware requirements.

As the manufacturers introduce smart technology they are also capable of producing items that work in harmony with other smart products in your home and this means that your kitchen or office will become more intuitive and even responsive to the needs that you have.

Sustainable Practices: Materials Coming To The Forefront Are Eco-Friendly

Sustainability is no more a buzzword, but rather it is a necessity. Today, hardware producers are devoting more effort to making custom cabinet hardware out of materials that are environmentally friendly without turning to compromise either in terms of quality or style. Sustainable resources are in the process of taking root, going even as far as recycled metals or even biodegradable plastic where the hardware product is concerned.

This trend to being greener is propelled by the consumers and the ecology. With an increase in population that values more on focusing on environment-friendly products, manufacturers are taking a trend by providing hardware solutions that minimize the damages to the environment caused by other conventional raw materials. These inventions are aiding in saving natural resources as well as waste materials and energy and cutting down wastage during the manufacturing process.

Furthermore, other manufacturers are developing hardware that would be fully recyclable which would enable the consumers to make a green choice ignoring durability issues and design.

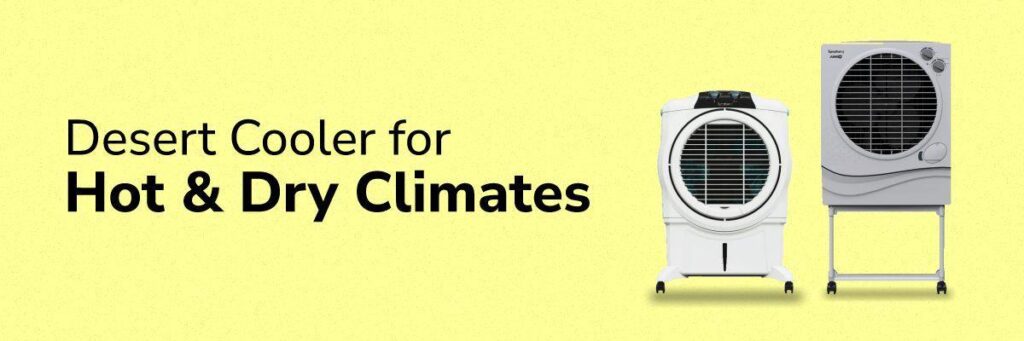

Improvements in Longevity and Performance

One of the most important considerations when selecting the custom cabinet hardware is durability. The Makers of the future are coming up with new materials and coatings to increase the lifespan and functionality of their products in 2025. To take an illustration, scratch resistant finishing and rust proof finishing are becoming popular, which means that the fasteners maintain good appearance over big durations.

More than materials, engineering and design innovations are also making things more useful. Cabinet hardware is more accommodating and easier to grip and open as well as close the cabinets and drawers. Other producers are installing smooth, self-closing mechanisms to hinges and handles that not only enhance the user experience, but it also increases the longevity of the hardware.

As it has always been emphasized on these two things such as durability and ease of handling, the manufacturers are making certain that custom cabinet hardware maintain the requirement of hurry-paced households and commercial areas where catering is done frequently to the hardware where durability is at stake.

The Future of 3D Printing and Customization in Design

Hardware manufacturing has not been left behind with regard to the 3D printing technology that has completely transformed many industries. In the year 2025, 3D printing will be adopted by the hardware manufacturers to provide increased customization and custom solutions. With this technology it is possible to produce custom made cabinet hardware that is specifically designed to meet the needs and demands of individuals.

Nowadays it is simpler than ever to manufacture small quantities of hardware with complicated designs, unusual shapes, and tailored sizes with 3D printing. Regardless of whether you want a particular finishing, dimension, or shape on your cabinet handles, 3D printing can give you the ability to turn your plan into reality with minimal wastages and much sooner than conventional solutions can offer you.

Such change to a 3D printing opens possibilities not only to more consumers to create really unique pieces, but also make the custom hardware accessible to more customers because, with the reduction in costs of mass production, even creating the hardware becomes more economical.

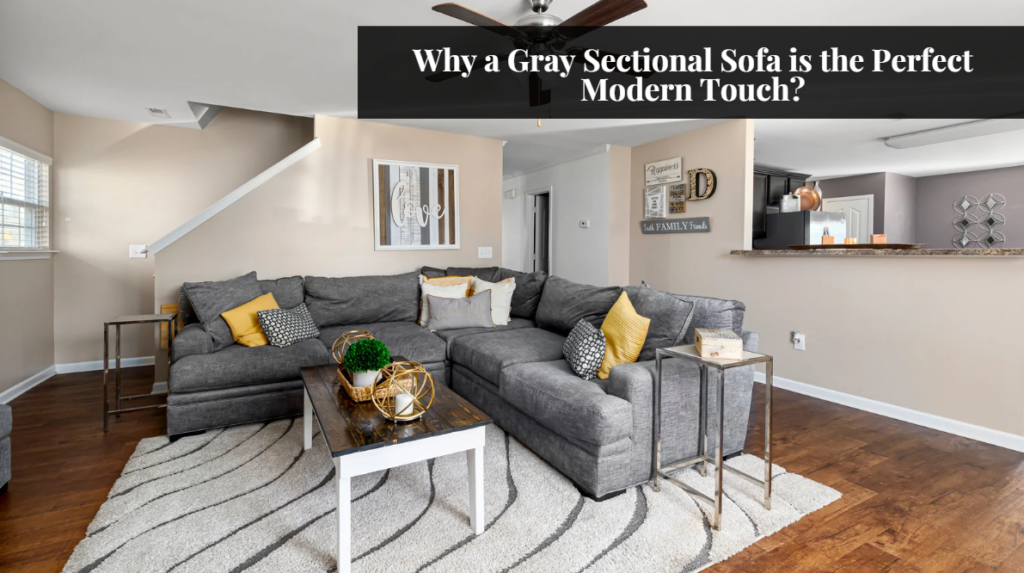

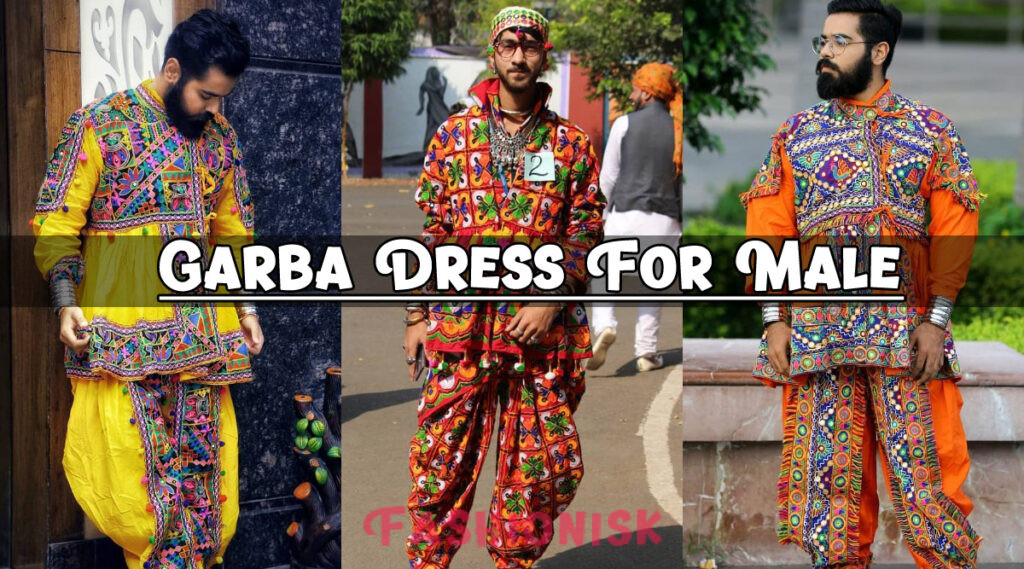

Blending of Aesthetics and Functional Design

By the year 2025, custom cabinet hardware is becoming more concerned with the design aspect that is both aesthetically and practically present. Manufacturers are collaborating with designers and architects to make hardware that will match the indoor design of the house all the time, and improve functionality. The modern versions are sleek, have minimalist and clean lines with simple features, but for those who want to make a difference, more artistic designs are the rage.

Designers are also concentrating on hardware that really flows to how the entire cabinetry is designed. An example is flush handles which become part of the design of the cabinet, or have built-in storage compartments. With form and functionality coming together, the manufacturers are making sure that bespoke cabinet hardware is serving the various requirements of current interiors.

The trend is stimulated by the growth in the popularity of custom designs in houses and business premises. People have stopped seeking standard hardware, they rather seek pieces that match their personality and design eye.

By 2025 the hardware manufacturers are boldly innovating and the custom cabinet hardware is becoming even more sustainable, functional and beautiful than ever. With smart technology and environmentally-friendly materials as well as 3D printing and ergonomic design, the industry is fast developing so as to appeal to the consumers who care about both beauty and performance.

When seeking hardware of custom cabinets that is a mixture of design, functionality and durability, there are many options that will excite you in the market. The future of cabinet hardware is becoming brighter, as these manufacturers are now engaging in continuous innovation and reshaping boundaries.