Top 7 Screen Printing Equipment You Need For Your Business Success

Starting or scaling a screen printing business can be exciting, but without the right equipment, success can be tough to achieve. Whether you’re printing t-shirts, tote bags, posters, or promotional products, having the right tools makes all the difference. Your final product’s quality, efficiency, and professionalism rely heavily on the equipment you choose.

To help you kickstart your business on the right foot, here’s a rundown of the essential pieces of screen printing equipment you need for your success.

Important Screen Printing Equipments List

Here’s the list of screen printing equipment you need for business success.

Screen Printing Press

The screen printing press holds the proper position to apply design ink. The selection between manual press mechanisms and electric press models exists based on financial resources and production targets.

Manual screen printing equipment works well for people starting out in the industry as well as any small shops. An automatic screen print machine will enhance productivity and consistency for printers wanting to increase their output level. Printers with multi-color functions and rotating platens help users produce elaborate designs efficiently.

Screens

A screen is a metal mesh frame that secures your stencil during use. Screen mesh counts vary to match the intricacy of artwork together with ink requirements.

Using high-quality screens leads to better image definition and easier printing quality. A wise design practice involves maintaining multiple screens for successful management between different clients as well as designs. A screen printer setup requires screens built to handle tension, durability, and other specified printing requirements as primary selection factors.

Emulsion

Your screen requires the application of a light-sensitive emulsion chemical that assists image transfer during the printing process before you start. The light exposure of your emulsion-coated screen creates a hardened stencil from your artwork design.

For educational purposes, three main categories of emulsion exist: diazo, dual-cure, and photopolymer. Your choice will depend on how intricate your designs are and how fast you want to reclaim and reuse screens. The proper implementation of emulsion has to be accompanied by a suitable emulsion scoop coater to achieve uniform application.

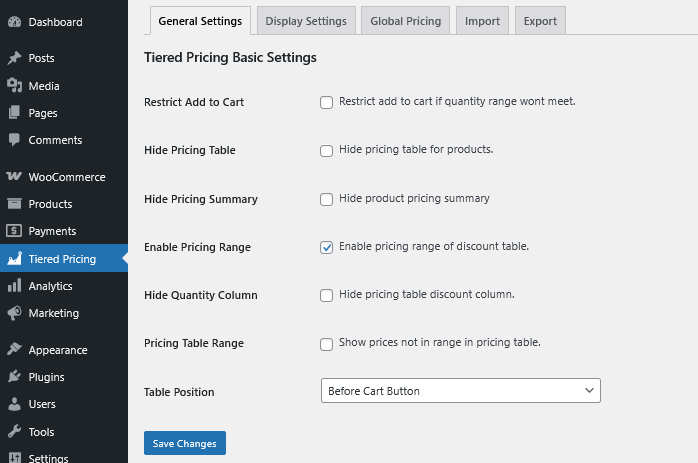

Computer

The main core of screen printing exists within design principles. A computer equipped with appropriate design software enables users to develop high-resolution artwork that they can modify. The design function serves as both a setup and layering tool and produces a color separation and final print execution.

A reliable system that assists workflow and customer file management should be purchased because of its worth. Software applications enhance output quality by producing precise results when your screen printing machine operates.

Squeegees

The vital and simple tool known as a squeegee serves to maneuver ink across the screen mesh so it bonds with the material. Each printing task requires its own unique blade specifications and hardness, which determine which squeegee to use in the process.

Printers should choose soft squeegees for dealing with textures and hard squeegees for handling fine printing details. Selecting various widths of squeegees enables easy adaptation to different projects. Your printing results heavily depend on keeping an excellent squeegee since it determines the final print outcome.

Exposure Unit

The exposure unit serves as the essential instrument that causes designs to materialize. The machine employs UV illumination to fix the emulsion while transferring your artwork to the screen when you apply light. The exposure unit stands as an essential part of the preparation method since it determines image clarity levels.

Exposed-screen printers can choose from basic tabletop units or invest in advanced vacuum units, which enable better contact and improved precision. The selection of an exposure unit depends on your studio volume and desired print quality outcome. A reliable exposure unit simplifies your preparation operations while minimizing the number of wasted resources that remain vital for screen printer success.

Drying Racks

Your materials require complete drying before finalization to prevent ink smudging and to allow the ink to be established correctly. Drying racks provide an appropriate method to let your printed materials dry through air circulation.

A conveyor dryer or flash dryer should be considered for businesses printing extensive print volumes. Stackable racks operate as space-saving solutions that allow appropriate airflow to permeate between each print. All professional screen printers need drying solutions regardless of their equipment scale.

Conclusion

Screen printing achievement relies on two components: inventiveness combined with the correct production resources needed to build visions practically. Each piece of screen printing equipment, from the press to the drying racks, plays a critical role in your workflow. In starting a screen printing business or seeking product quality improvement, you should invest in high-quality tools that directly enhance your end results.

A combination of an excellent screen printing machine and durable screens paired with dependable computer hardware and suitable finishing systems will enable you to create top-quality prints that will delight your clients and increase your revenue. You need to invest in proper equipment because it determines your business achievement.