How Nitrile Gloves Compare to Latex and Vinyl: A Comprehensive Guide

In today’s world, personal protective equipment (PPE) is more crucial than ever. Among PPE, gloves play a vital role in safeguarding our health, particularly for healthcare professionals, laboratory workers, and food handlers. With various options available, deciding between nitrile, latex, and vinyl gloves can be confusing. Each type has unique characteristics that make them suitable for specific tasks. This comprehensive guide will help you understand the differences between nitrile glove, latex, and vinyl gloves, ensuring you make an informed choice for your needs.

The Basics of Nitrile Gloves

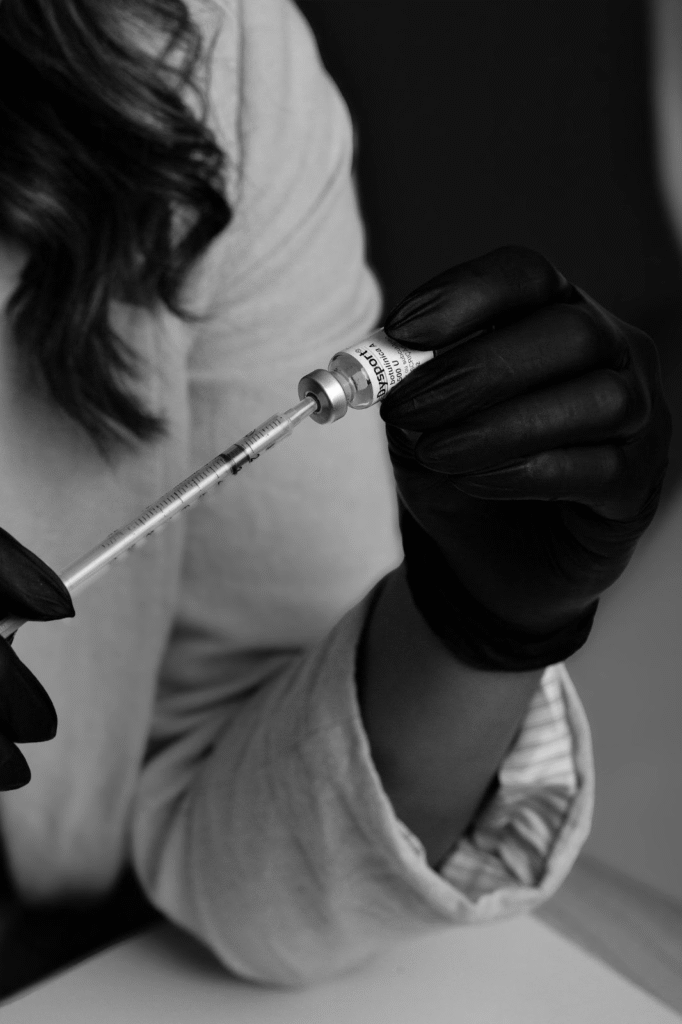

Nitrile gloves are made from synthetic rubber, offering several advantages over their counterparts. They are especially popular among those who require a latex-free option due to allergies. Nitrile gloves provide excellent resistance to punctures, chemicals, and oils, making them suitable for various environments.

The manufacturing process of nitrile gloves involves the polymerization of acrylonitrile and butadiene, which are then combined to form a durable, flexible material. This process results in gloves that are highly resistant to tears and punctures, while still maintaining a comfortable fit. Additionally, nitrile gloves provide excellent tactile sensitivity, allowing users to perform intricate tasks with ease.

In terms of cost, nitrile gloves tend to be more expensive than latex and vinyl gloves. However, their durability and versatility often justify the higher price tag. They are ideal for medical professionals who require a reliable, long-lasting glove that won’t compromise their safety during critical procedures.

Unpacking Latex Gloves

Latex gloves have been a staple in the healthcare industry for decades. Made from natural rubber, they offer a combination of comfort, flexibility, and protection. These gloves provide an excellent barrier against pathogens and contaminants, making them a popular choice for medical professionals.

One of the main benefits of latex gloves is their superior elasticity, which allows them to fit snugly on the hand. This close fit enhances tactile sensitivity, enabling users to perform delicate tasks with precision. Additionally, latex gloves are biodegradable, making them an environmentally friendly option compared to synthetic alternatives.

However, latex gloves are not without their drawbacks. A significant concern is the potential for allergic reactions, which can range from mild skin irritation to severe anaphylactic responses. For this reason, many organizations have transitioned to latex-free alternatives like nitrile and vinyl gloves to accommodate individuals with latex allergies.

Vinyl Gloves Explained

Vinyl gloves are made from polyvinyl chloride (PVC), a synthetic material that offers an affordable alternative to nitrile and latex gloves. They are widely used in the food industry, as well as for low-risk tasks in healthcare and cleaning environments.

One of the primary advantages of vinyl gloves is their cost-effectiveness. They are typically less expensive than nitrile and latex gloves, making them an attractive option for businesses looking to save on PPE expenses. Vinyl gloves are also latex-free, providing a suitable option for individuals with allergies.

Despite their affordability, vinyl gloves have some limitations. They tend to be less durable and offer lower resistance to punctures and chemicals compared to nitrile and latex gloves. Additionally, vinyl gloves have a looser fit, which can compromise tactile sensitivity and dexterity. This makes them less suitable for tasks that require precision and accuracy.

Comparing Puncture Resistance

When it comes to puncture resistance, nitrile gloves are the clear winner. Their robust construction makes them highly resistant to tearing and punctures, providing a reliable barrier against potential hazards. This makes nitrile gloves an ideal choice for industries that require heavy-duty protection, such as automotive, medical, and laboratory settings.

Latex gloves offer moderate puncture resistance, making them suitable for everyday use in healthcare environments. However, they may not provide adequate protection in situations where sharp objects or hazardous chemicals are present.

Vinyl gloves have the lowest puncture resistance among the three types. While they are suitable for low-risk tasks, they may not provide sufficient protection in environments where punctures are a concern. It’s essential to consider the level of protection needed for your specific application when choosing between these glove types.

Understanding Chemical Resistance

Chemical resistance is another crucial factor to consider when selecting gloves. Nitrile gloves excel in this area, offering excellent protection against a wide range of chemicals, including oils, solvents, and acids. This makes them suitable for use in laboratories, automotive workshops, and other environments where chemical exposure is a concern.

Latex gloves provide moderate chemical resistance, making them suitable for tasks that involve limited chemical exposure. However, they may not offer adequate protection against more aggressive substances, such as strong acids and solvents.

Vinyl gloves offer the least chemical resistance of the three types. While they can protect against mild chemicals, they may not withstand prolonged exposure to harsher substances. When working with chemicals, it’s essential to choose gloves that provide the appropriate level of protection for your specific needs.

Examining Comfort and Fit

Comfort and fit are crucial factors to consider when selecting gloves, as they can impact the user’s ability to perform tasks effectively. Latex gloves are renowned for their superior elasticity and snug fit, which enhances tactile sensitivity and dexterity. This makes them a popular choice for tasks that require precision and accuracy.

Nitrile gloves offer a comfortable fit and excellent tactile sensitivity, making them suitable for a wide range of applications. While they may not provide the same level of elasticity as latex gloves, they still offer a close fit that allows for easy manipulation of objects.

Vinyl gloves tend to have a looser fit compared to nitrile and latex gloves. This can compromise tactile sensitivity and dexterity, making them less suitable for tasks that require precision. However, they can still provide adequate comfort for low-risk tasks that don’t require a high level of dexterity.

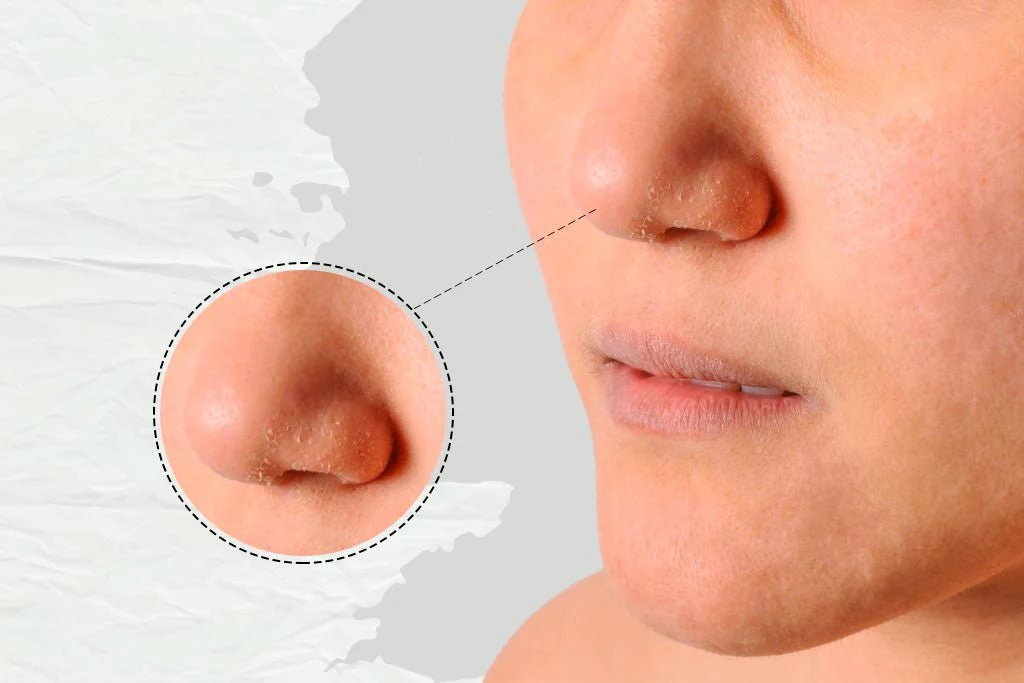

Considering Allergy Concerns

Allergies are a significant concern when it comes to selecting gloves. Latex gloves can cause allergic reactions in some individuals, ranging from mild skin irritation to severe anaphylactic responses. For this reason, many organizations have transitioned to latex-free alternatives like nitrile and vinyl gloves to accommodate individuals with latex allergies.

Nitrile and vinyl gloves are both latex-free, making them suitable options for those with latex sensitivities. While nitrile gloves are generally considered to be hypoallergenic, some individuals may still experience mild skin irritation due to the chemicals used in the manufacturing process. In such cases, vinyl gloves may be a more suitable option.

Evaluating Environmental Impact

The environmental impact of gloves is an important consideration for many organizations. Latex gloves are biodegradable, making them a more environmentally friendly option compared to synthetic alternatives like nitrile and vinyl gloves.

Nitrile gloves, while not biodegradable, are recyclable through specialized recycling programs. These programs can help reduce the environmental impact of nitrile gloves by repurposing used gloves into new products.

Vinyl gloves have the highest environmental impact of the three types, as they are neither biodegradable nor easily recyclable. When considering the environmental impact of gloves, it’s essential to weigh the benefits of each type against their potential ecological footprint.

Identifying Cost-Effectiveness

Cost-effectiveness is a crucial factor for many organizations when selecting gloves. Vinyl gloves are typically the most affordable option, making them an attractive choice for businesses looking to save on PPE expenses. However, their lower durability and chemical resistance may limit their suitability for certain tasks.

Nitrile gloves tend to be more expensive than vinyl gloves, but their superior durability and chemical resistance often justify the higher price tag. They are an ideal choice for environments that require reliable, long-lasting protection.

Latex gloves fall somewhere in between nitrile and vinyl gloves in terms of cost. They offer a balance of comfort, durability, and affordability, making them a popular choice for healthcare professionals.

Exploring Industry Applications

Different industries have varying requirements when it comes to gloves. In the healthcare industry, nitrile and latex gloves are popular choices due to their excellent barrier protection and tactile sensitivity. Nitrile gloves, in particular, are favored for their resistance to punctures and chemicals.

In the food industry, vinyl gloves are commonly used due to their affordability and latex-free composition. However, nitrile gloves are gaining popularity for their durability and chemical resistance, which can help prevent cross-contamination.

In industrial settings, nitrile gloves are often the preferred choice due to their robust construction and chemical resistance. Latex gloves may also be used for tasks that require a high level of dexterity and tactile sensitivity.

Assessing Tactile Sensitivity

Tactile sensitivity is an important consideration for tasks that require precision and accuracy. Latex gloves are known for their superior tactile sensitivity, making them a popular choice for tasks that require fine motor skills.

Nitrile gloves offer excellent tactile sensitivity, allowing users to perform intricate tasks with ease. While they may not provide the same level of sensitivity as latex gloves, they still offer a comfortable fit and reliable protection.

Vinyl gloves offer the lowest tactile sensitivity of the three types. While they may be suitable for low-risk tasks, they may not provide the level of precision required for more intricate tasks.

Discovering the Right Glove for Your Needs

Ultimately, the right glove for your needs will depend on a variety of factors, including the level of protection required, potential allergy concerns, and cost considerations. Nitrile gloves are an excellent choice for environments that require robust protection against punctures and chemicals, while latex gloves offer superior tactile sensitivity for tasks that require precision.

Vinyl gloves are a cost-effective option for low-risk tasks, but may not provide the level of protection needed for more demanding environments. By understanding the unique characteristics of each glove type, you can make an informed decision that best meets your specific needs.

Final Thoughts

Choosing the right gloves is essential for ensuring the safety and comfort of both you and your employees. By understanding the differences between nitrile, latex, and vinyl gloves, you can make an informed decision that meets the specific needs of your workplace. Whether you require robust protection against chemicals or superior tactile sensitivity for intricate tasks, there’s a glove option that will provide the protection you need.