Understanding the Toilet Flush Valve: Key Features and Maintenance

In the realm of home improvement and maintenance, understanding the intricate workings of a toilet flush valve might seem trivial at first glance. However, for those seeking to maintain a smoothly functioning household, it’s a detail that shouldn’t go overlooked. From preventing unwanted water waste to ensuring that your bathroom remains a reliable oasis, the flush valve plays a crucial role. This guide is designed to unravel the complexities of toilet flush valve, offering insights into their key features and how to keep them in top shape.

Modern Bathroom Remodel trends emphasize minimalism, eco-friendliness, and luxurious finishes. Integrating sustainable materials, water-saving fixtures, and sleek design elements helps create a contemporary and environmentally responsible bathroom that’s both stylish and functional, meeting current design preferences and future needs.

The Unsung Hero of the Bathroom

At the heart of every efficient toilet is the flush valve, an often underappreciated component that controls the release of water during a flush. When you press the handle, the valve opens, allowing water to rush from the tank into the bowl, effectively flushing waste down the drain. It’s a straightforward process, yet one that relies heavily on the valve’s integrity and functionality.

Understanding this mechanism is the first step toward appreciating its significance. A well-functioning flush valve ensures a powerful flush while minimizing water usage, which is vital not only for the environment but also for your water bill. By familiarizing yourself with its operation, you can identify potential issues before they escalate, saving you from costly repairs.

Key Features of a Toilet Flush Valve

Material Matters

Flush valves are crafted from various materials, each offering distinct advantages. Common options include plastic, brass, and stainless steel. Plastic valves are often found in standard toilets due to their affordability and resistance to corrosion. Brass, known for its durability, is an excellent choice for those seeking longevity, though it comes at a higher price point. Stainless steel combines strength and rust resistance, making it a popular choice for high-end models.

Selecting the right material can significantly impact the lifespan of your flush valve. Consider factors such as water quality in your area and budget constraints when making your decision. Remember, investing in a durable material upfront can save you from frequent replacements down the line.

Size and Compatibility

Flush valves come in various sizes, typically ranging from 2 to 4 inches in diameter. The size directly affects the flow of water during a flush. Larger valves allow more water to rush into the bowl, resulting in a more powerful flush. However, it’s crucial to choose a valve size compatible with your toilet model to avoid installation issues.

Before purchasing a new flush valve, measure the existing one or consult your toilet’s manual for specifications. Installing an incompatible valve can lead to leaks or inefficient flushing, negating the purpose of the upgrade.

Adjustable Features

Modern flush valves often feature adjustable components, allowing users to customize their flush settings. This flexibility is particularly useful for households aiming to conserve water. Adjustable flappers, for instance, enable users to control the duration the valve stays open, thereby regulating water usage.

By experimenting with these settings, you can achieve a balance between a thorough flush and water conservation. Regularly monitoring and adjusting your valve’s settings can lead to significant savings over time, both financially and environmentally.

Common Issues and Troubleshooting

Leaky Valves

One of the most prevalent flush valve issues is leakage, which can result in wasted water and increased utility bills. Identifying the source of the leak is the first step in resolving this problem. Often, a worn-out flapper is to blame. Over time, flappers can deteriorate, leading to a poor seal and constant water flow.

To fix a leaky valve, start by inspecting the flapper for signs of wear and tear. If it appears warped or damaged, replacing it is a straightforward task. Be sure to turn off the water supply before removing the old flapper and installing the new one. This simple fix can make a significant difference in your toilet’s efficiency.

Weak Flush

Another common issue is a weak flush, characterized by incomplete waste removal. This can result from a partially closed valve or a clogged rim feed. First, check that the flush valve is fully opening during each flush. If it’s not, adjusting the chain length connected to the handle can often resolve this issue.

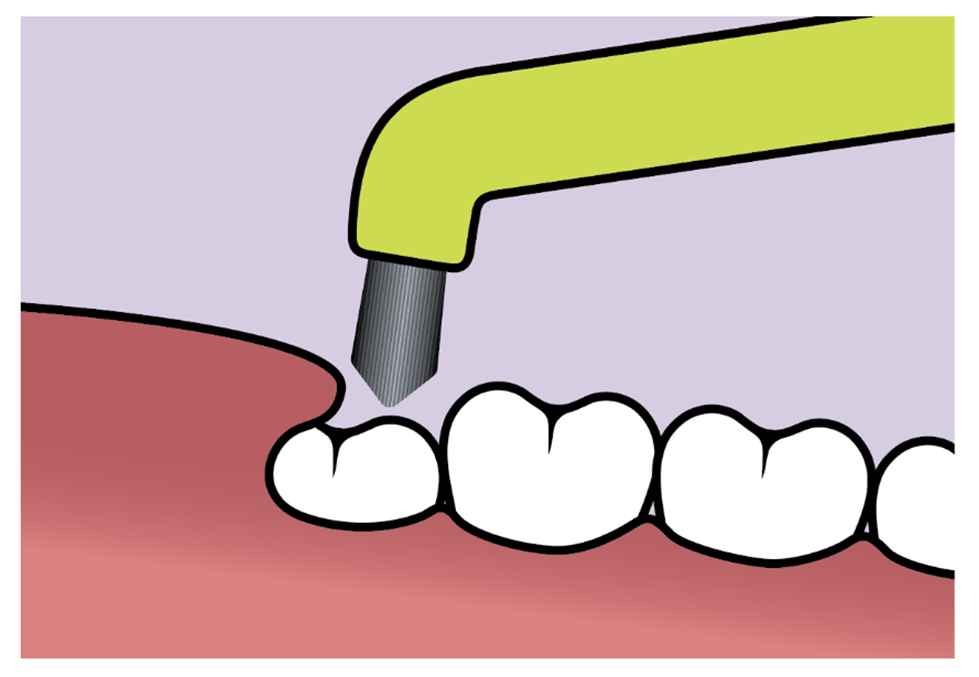

For issues related to the rim feed, mineral deposits may be restricting water flow. Cleaning the rim holes with a wire hanger or a specialized brush can restore full functionality. Regular maintenance prevents such build-up, ensuring your toilet operates at peak performance.

Constant Running

A constantly running toilet is not only annoying but also wasteful. This issue often stems from an improperly seated flapper or an issue with the fill valve. Begin troubleshooting by checking the flapper’s alignment. Ensure it’s securely closing over the valve seat after each flush.

If the flapper is functioning correctly, examine the fill valve for potential obstructions. Sediment or debris can interfere with its operation, causing continuous water flow. Cleaning the fill valve and ensuring it’s free from clogs can resolve this problem and restore tranquility to your bathroom.

Maintenance Tips for Longevity

Regular Inspections

Routine inspections are essential for maintaining a healthy flush valve. Check for visible signs of wear or damage, such as cracks or discoloration. Addressing minor issues promptly can prevent them from escalating into major problems, ensuring your toilet remains efficient and reliable.

Create a maintenance schedule that includes periodic checks of your toilet’s components. This proactive approach extends the lifespan of your flush valve and minimizes the likelihood of unexpected repairs.

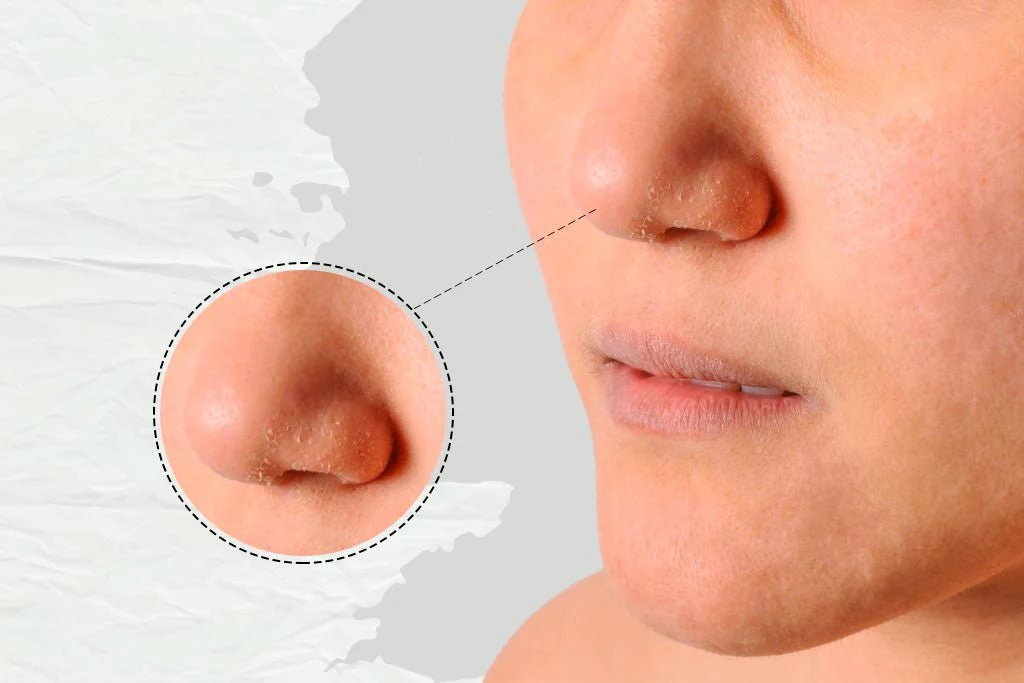

Cleaning and Descaling

Cleaning your flush valve and surrounding components is crucial for preventing mineral build-up. Hard water, rich in minerals like calcium and magnesium, can lead to scaling, impairing the valve’s functionality. Vinegar is an effective natural remedy for descaling your toilet components.

Simply soak affected parts in vinegar or apply it directly with a brush to dissolve mineral deposits. Regular cleaning not only enhances performance but also maintains a hygienic environment in your bathroom.

Replacing Worn Parts

Despite regular maintenance, parts of your flush valve may wear out over time. Knowing when to replace these components is key to avoiding disruptions in your toilet’s operation. Flappers, chains, and seals are common parts that require periodic replacement.

Keep spare parts on hand to facilitate quick repairs and minimize downtime. Familiarize yourself with the replacement process to ensure a smooth transition when the need arises. Proactive part replacement is an investment in your toilet’s long-term performance.

Conclusion

The toilet flush valve may seem like a humble component, but its role in maintaining an efficient and functional bathroom is indisputable. Understanding its key features and common issues empowers homeowners to address problems promptly and maintain their toilets in optimal condition.

By implementing regular maintenance practices and staying vigilant for signs of wear, you can extend the lifespan of your flush valve and enjoy a smoothly operating bathroom. For those seeking further guidance or professional assistance, numerous resources are available to enhance your plumbing knowledge.

Investing time in understanding and maintaining your toilet flush valve pays off in both convenience and cost savings. Here’s to a future where plumbing mishaps are a thing of the past!