How to Turn Your Garage or Basement into a Stylish Oasis in Just One Day

Plenty of homes hide valuable square footage in plain sight. The unfinished garage stacked with holiday boxes, the basement that smells faintly of concrete dust, the cold slab underfoot that makes evenings feel less welcoming than they should. Picture stepping onto a surface as sleek as a boutique showroom yet tough enough to shrug off tire marks, spilled coffee, and winter salt. Visualize it coming together before dinner tonight, with no lingering odor or days-long wait to park the car again. The secret lies in next-generation polyurea and polyaspartic coatings paired with a streamlined installation process. When style meets high performance and rapid-cure chemistry, underused rooms gain fresh life, improved comfort, and undeniable visual appeal. This guide walks you through every step, from hidden potential to color inspiration, budgeting, and maintenance, so you can claim every inch of your home with confidence.

Why Concrete Floors Deserve a Style Upgrade

The Untapped Potential of Forgotten Spaces

Garages and basements often end up as afterthoughts. Car tyres, lawn tools, holiday decorations, and workout gear pile up until movement feels like an obstacle course. Yet these zones carry structural strength, access to power, generous ceiling heights, and direct links to the outdoors. Finishing the floor creates an instant sense of completion, prompting owners to reimagine possibilities. A coated surface brightens light levels, softens acoustic echo, and invites design cues from the rest of the home. When the foundation looks polished, walls and décor follow, unlocking room for home gyms, creative studios, or a cozy lounge for weekend movie nights. In short, polished concrete expands living space without knocking down walls.

Between Ugly & Functionless: Common Problems Concrete Floors Create

Raw concrete excels at load bearing but falls short in day-to-day livability. Porous material breathes dust into the air and wicks moisture onto stored boxes. Tiny cracks crawl across the surface during seasonal temperature shifts, while automotive fluids seep in and leave permanent stains. The neutral grey absorbs light, making even a clean garage look dim and unfinished. Upgrading with garage & basement coatings locks down the surface, stops dust, seals against spills, and introduces color-chip patterns that transform utility space into a striking design statement. The result is a floor that reads purposeful, elegant, and ready for anything family life throws its way.

Meet Polyurea & Polyaspartic: The Design-Ready Flooring Options

What Makes Them Superior: durability, low VOC, fast cure, UV stability

Many homeowners heard about epoxy garage floors two decades ago. Although epoxy still improves appearance, modern polyurea and polyaspartic chemistry raises every performance metric. Polyurea forms flexible cross-links that resist impact and abrasion four times better than epoxy. Low solvent content keeps odor minimal during application, a welcome relief for households with kids and pets. Rapid chemical cure lets technicians walk on the floor within hours, not days, slashing downtime and eliminating the infamous sticky window common to slow-curing epoxies. Polyaspartic top coats further boost UV stability, so bright or bold colors stay true season after season. Independent lab tests confirm tensile strength above 4,500 psi and elongation rates that handle thermal shock without spider cracking—critical for regions with snowy winters and hot summers.

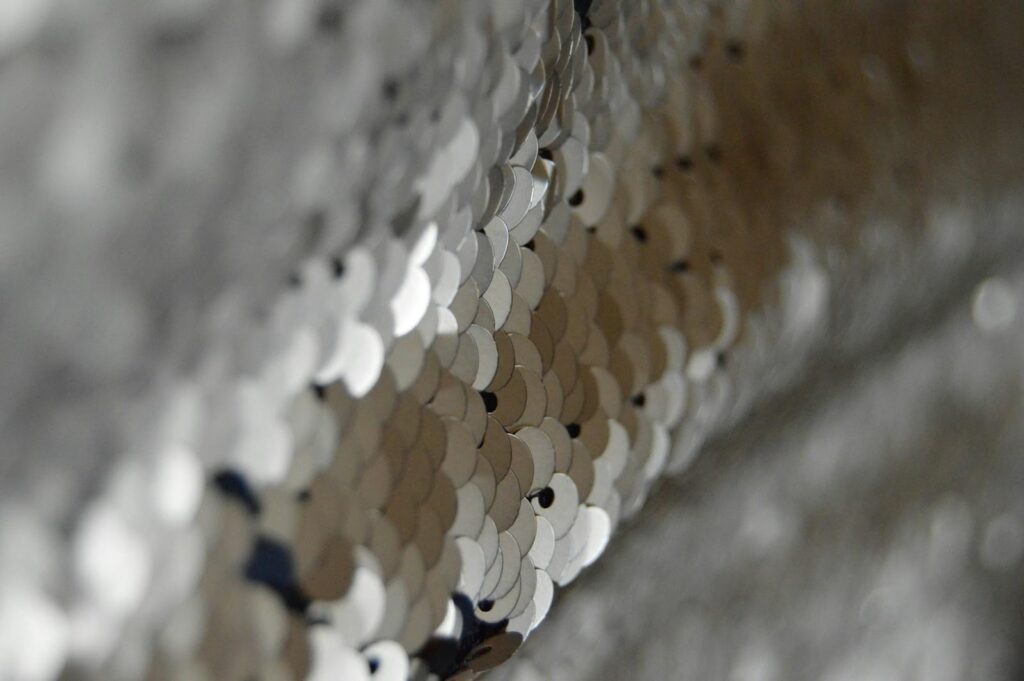

Color & Texture Options That Suit Every Aesthetic

Performance does not sacrifice personality. Installers broadcast decorative vinyl flakes or quartz chips into the wet base coat, then seal everything beneath a clear polyaspartic glaze. The result mimics terrazzo, granite, or smooth stone without the cost of natural materials. Driftwood blends lean into Scandinavian minimalism, while Pebble Beach or Mediterranean mixes lend resort vibes to a basement lounge. Pigmented base coats also accept metallic mica for a liquid-swirl effect popular in boutique fitness studios. Such variety proves that industrial concrete coatings can look refined enough for living rooms while still outperforming products developed for heavy industry. Homeowners choose from flexible color decks, chip sizes, and matte or gloss sheens, ensuring the finished room flows with existing décor rather than feeling tacked on.

What Happens in a Day – The 1-Day Installation Process

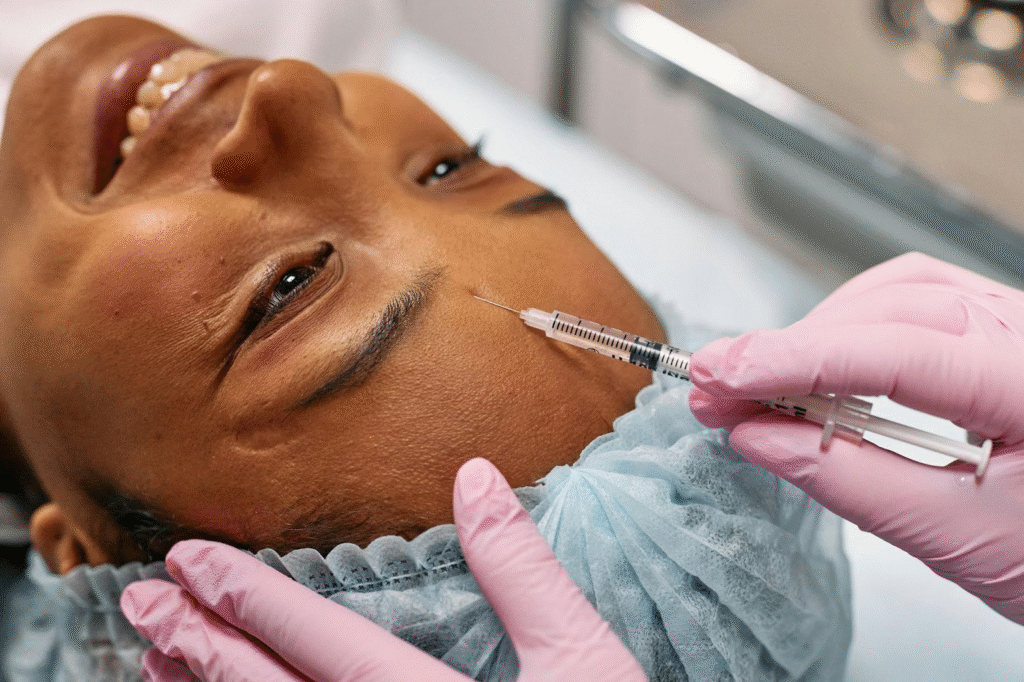

Step 1: Prep & Concrete Grinding

Every transformation begins with surface preparation. Installers move furniture into mobile storage pods or tarp-protected corners, then run a planetary grinder equipped with diamond tooling across the slab. This step opens pores, evens minor waves, and removes old sealers. Next comes crack repair with fast-setting polyurea patch material, followed by a meticulous vacuum pass that leaves a clean, textured canvas ready to bond with fresh resin.

Step 2: Base Coat, Flakes, Top Coat for Quick Cure and UV-Stable Protection

A pigmented polyurea base coat rolls on in a single, even pass, wetting into micro-fractures for a chemical anchor stronger than the concrete itself. Within minutes, installers broadcast decorative flakes until no wet gloss shows, building both color depth and slip resistance. After a short curing window—often twenty to thirty minutes depending on temperature—they reclaim excess flakes and lightly scrape high spots. A clear polyaspartic top coat follows, flowing over the chips, locking them in place, and creating a seamless, non-porous finish. Thanks to rapid cross-linking, the surface supports foot traffic before sunset and vehicle tyres the following morning.

Storage & Cleanup: Minimal Disruption, Maximum Convenience

Because the materials cure so quickly, homeowners regain use of the space almost immediately. Tools roll back to their hooks, bikes return to wall racks, and cars sleep inside the garage the next night. Shelly Smith captures the experience: “The crew went above and beyond and I was impressed it only took them one day to do the whole project!” – Shelly Smith . Tom Biel adds, “I wanted something for my garage that would last longer than traditional epoxy… the crew even removed and stored everything that was in my garage.” – Tom Biel

Design Inspirations to Spark Your Style

Home Gym Vibes: Sleek Slate or Driftwood Tones

An at-home fitness zone thrives on subtle texture that grips rubber shoes yet cleans easily after a vigorous workout. Slate and Driftwood blends provide cool, calming greys that pair well with stainless-steel equipment and wall-mounted mirrors. Add LED strip lighting under shelving to highlight gentle flake variation, and the room feels like a private studio ready for sunrise yoga.

Man Cave or She-Shed: Bold Granite or Custom Colors

Lounge spaces beg for personality. Granite chip blends featuring charcoal, silver, and sapphire chips create dramatic depth beneath leather seating and statement lighting. For a craft corner or She-Shed, installers can mix a custom palette—think blush with pearl highlights—to match soft furnishings. The fully sealed surface shrugs off spilled paint, sawdust, or an occasional dropped hammer, making creativity carefree.

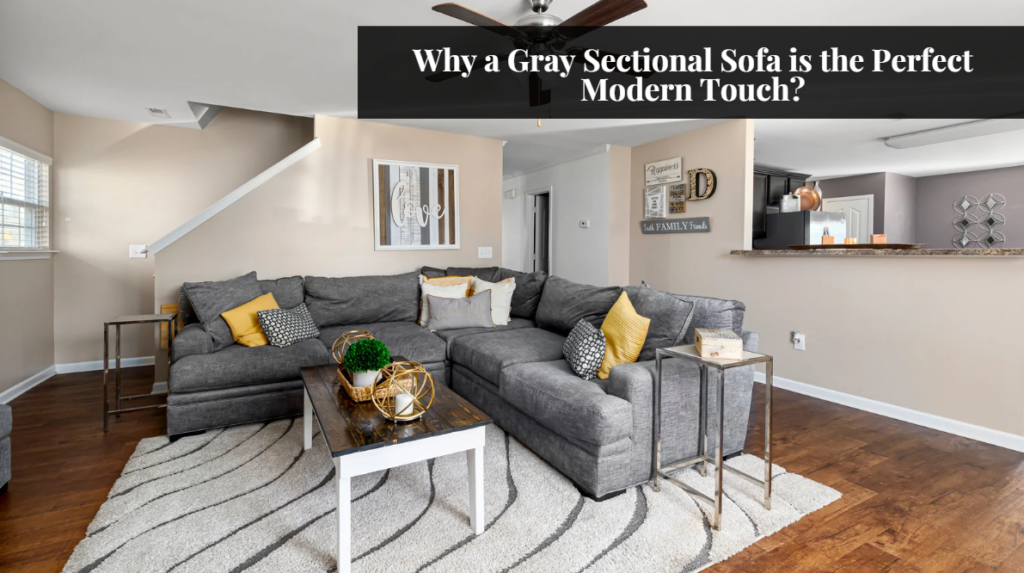

Chic Basement Lounge: Mediterranean, Pecan, or Domino Finishes

Basements often lack natural light, so color choice matters. Mediterranean delivers sandy beige with hints of sea-glass blue that bounce warm light from floor lamps. Pecan adds caramel notes that complement wood paneling or cognac-toned sectionals. Domino—crisp black-and-white chips in equal measure—creates a graphic foundation ideal for minimalist furniture and gallery-style art walls.

Long-Term Benefits: Style That Stands the Test of Time

Fifteen-Year Durability vs Epoxy’s Five- to Ten-Year Span

Surface beauty means little without staying power. Industry data show that polyurea systems often carry warranties of fifteen years or longer, while basic epoxy coatings require touch-ups or full replacement every five to ten. Polyurea resists hot-tyre pickup, road salt, and UV fade, so the color selected this weekend looks the same a decade later. Because the coating forms a single membrane, moisture vapour cannot dislodge it from beneath, a common failure mode for epoxy in humid regions. By choosing garage floor coatings, households avoid the cycle of patching and recoating, saving both money and time over the life of the property.

Easy-Care, Chemical- and Water-Resistant

Once the surface cures, cleaning routines simplify dramatically. A soft-bristle broom gathers loose debris in minutes. For deeper cleaning, a mild pH-neutral soap and microfiber mop lift dust without dulling the top coat. Oil or brake fluid wiped within twenty-four hours leaves no trace thanks to complete pore sealing. In basements prone to dampness, the impermeable membrane blocks water vapour, reducing musty odours and protecting stored textiles. Pet owners appreciate that claw scratches and muddy paw prints rinse away without staining.

Budgeting for a Stylish Upgrade

What Goes into Pricing

Square footage sets the baseline for any project quote. Two-car garages average around 400 square feet, while finished basements range from 600 to 1,200 based on layout. Material blend also influences cost; metallic pigments or custom flake mixes add a premium due to specialty additives. Labour covers surface repair, crack filling, moisture testing, and disposal of old sealers. Some installers provide mobile storage pods or handling crews to move bulky items, adding a small fee yet saving homeowner effort. Geographic region affects hourly rates and local code requirements, though most residential projects remain far less intrusive than a full flooring replacement.

Why One-Day Polyurea Delivers Better ROI than Cheap Alternatives

A bargain epoxy kit may cost half as much initially, but frequent repairs, yellowing, and eventual replacement double total spend within a few years. Polyurea’s longer service life, reduced maintenance supplies, and higher perceived property value offset its upfront investment. The ability to complete the work in a single day eliminates hotel stays or storage rentals, further improving real ROI.

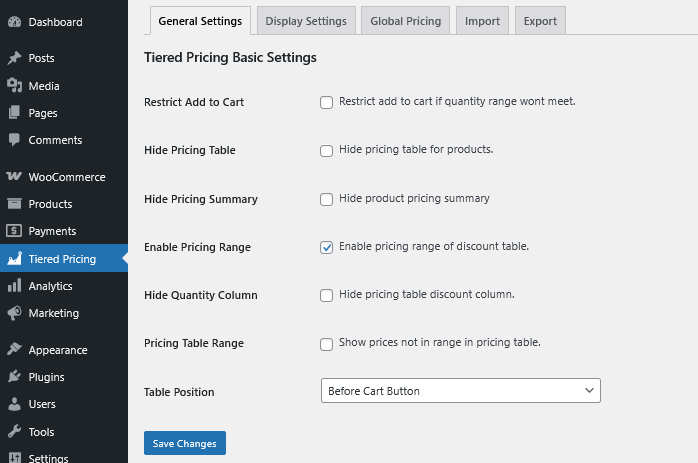

Before-You-Book Checklist: Key Points to Clarify

Permits, Prep, Warranty, Installer Credentials

Professional crews follow local building codes, yet many residential floor projects fall below formal permit thresholds. Still, confirm municipal rules to avoid penalties. During consultation, request details about dust-control equipment, slab-moisture testing, and crack-repair materials. A written warranty covering both product and labour, ideally lasting at least fifteen years, signals confidence. Finally, verify technician training certificates and insurance coverage. Reliable providers share photos of recent projects and connect prospective clients with past customers.

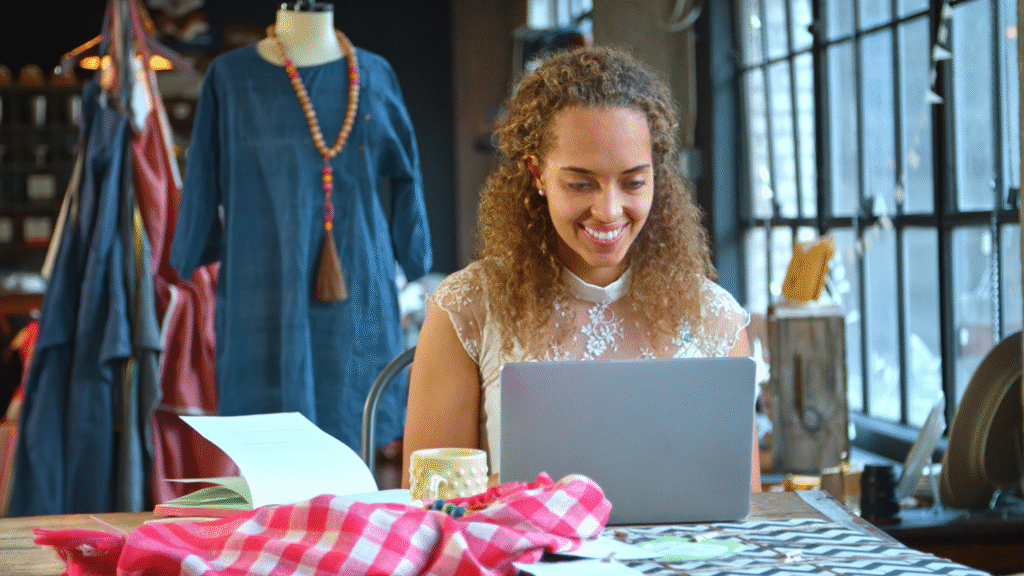

Align the Process with Your Aesthetic Vision

Bring mood-board images or colour swatches to your estimate appointment. Discuss flake density, gloss level, and slip-resistance additives, especially if children or older adults use the space. Clear communication up front ensures the installer brings correct pigments on coating day, keeping timelines tight and results on target.

Case Study Snapshot

A young family converted a dusty, 800-square-foot basement into an entertainment lounge in a single weekend. Day one centred on flooring. After grinding and crack repairs, the crew applied a warm Pecan base coat, then broadcast a custom mix of caramel, vanilla, and espresso chips. By late afternoon, the polyaspartic clear coat gleamed under recessed lighting. Day two, the family returned furniture and installed a projector for movie nights. The homeowners now spend “at least four evenings a week” enjoying the space, a dramatic shift from previously using the area only for storage. Maintenance involves a quick vacuum pass each Sunday and an occasional damp mop. They estimate the renovation cost just eight percent of what a full remodel would have required, proving small aesthetic upgrades can yield outsized lifestyle gains.

Ready to Elevate Your Space?

Concrete does not have to look cold or feel unfinished. Modern chemistry combines with professional craftsmanship to deliver showroom-worthy results in a single day, freeing homeowners from dust, stains, and downtime. With enduring colour, industry-leading strength, and endless design flexibility, polyurea and polyaspartic coatings unlock the full potential of garages and basements. Explore colour samples, gather inspiration photos, and schedule a consultation to discover how a fresh surface can expand living space, reflect personal style, and add measurable value to the place you call home.